Category Archives: Education

When it comes to drug creation and formulation, ensuring that both the creator and the property are protected is key. That is why it is important to understand what your intellectual property rights are, and how to defend them even after FDA review and distribution.

With that in mind, check out our informational guide on intellectual property protection, and how it applies to the pharmaceutical industry.

An Overview of Intellectual Property Protection

Intellectual property protection was established to legally safeguard ideas and inventions of the mind. This includes original pieces of work, such as artistic creations, symbols, names, manufacturing processes, pharmaceutical formulas, and beyond.

Intellectual property also comes in various forms depending on the medium of the work. The main types that you should be familiar with relate to the following:

- Patents

- Data exclusivity

- Trade secrets

- Copyright

- Trademarks

- Regulatory exclusivity

Why Is Intellectual Property Protection Vital in the Pharmaceutical Industry?

The protection of intellectual property in the pharmaceutical industry allows pharmaceutical creators to benefit fiscally from both idea fabrication and product manufacturing. Additionally, some of the reasons that intellectual property is legally protected and closely monitored include the following:

- Promotes continuous innovation – Since patents and other intellectual property types provide outside investors with the motive to put money into the research phase of drug creation, pharmaceutical scientists can continually work on evolving existing developments. Along with manufacturing and distributing current drugs, scientists can also create new drugs and start desired projects while knowing that their progression is being fully supported financially.

- Increases economic growth – Due to the ongoing process and competition that comes with bringing new drugs to the market, the creation of pharmaceuticals can produce further economic opportunities, such as generating new jobs and boosting overall exports on a global scale.

- Prevents misuse and confusion – With intellectual property protection, the rights to the formula and branding of a product belong solely to the company or individual who created it. That means consumers will know exactly who and where the product has come from, as well as what the intention of the specific product is. This will avoid misuse of the product itself, as well as confusion about the specifications of the product.

Overall, the protection of intellectual property increases innovative initiatives for companies looking to cultivate and expand upon drug development ideas and procedures. Alongside the developmental period for pharmaceuticals, intellectual property measures also legally protect creators from property infringement by competitors, ultimately boosting the production, distribution, and consumption of necessary medications.

A Brief History of Pharmaceutical Intellectual Property Protection

When it comes to protecting the creation of new drugs, applications, and research, intellectual property protection is crucial. The origins of intellectual property are not new ideas either, as the first instances of intellectual property disputes and one-year patent statements date back as far as 500 B.C.E.

In the modern era, there have been numerous cases that have shaped how we navigate property ownership and distribution. Alongside those cases, here are just some of the notable historical events that have progressed intellectual property rights:

- 1928 – Alexander Fleming discovered penicillin at St. Mary’s Hospital in London. This discovery marked the beginning of the antibiotic age, which lasted until around 1970, with 1940 to the early 1960s being considered the true golden age of the antibiotic era. During this time as well, product patents for drugs became more prevalent as growth and expansion prospered, though global drug patents were first introduced for the pharmaceutical industry in the late 17th century.

- 1984 – The Hatch-Waxman Act was established in the United States, laying the foundation both legally and economically for the U.S.’s generic pharmaceutical industry. And as more countries, such as Canada, began to recognize the importance of drug patents as well, multinational corporations (MNCs) within the pharmaceutical industry started to advocate on a global level for stronger intellectual property protection and patent laws for their products.

- 1994 – The TRIPS Agreement was established in this year and set minimum enforceable standards for various forms of intellectual property across numerous industries. For the pharmaceutical industry, it required countries part of the World Trade Organization (WTO) to make patents available for any products or processes without discrimination, completely replacing the “process patent” system that was in place at the time.

- 2000 onward – Patent thickets, evergreening, and consolidation practices become highly common in the pharmaceutical industry. Also during this time, we saw large lobbying efforts in the United States to try to prevent price controls from stopping skyrocketing prices on necessary drugs. This includes key bills, such as The Inflation Reduction Act of 2022.

FAQs – Additional Aspects to Consider

For more of an in-depth look at intellectual property protection and how to navigate the main types, check out the answers to some of our most commonly asked questions.

How long do patents last on new drugs?

As of this writing, patents last 20 years from the filing date listed on the patent application. Once a drug patent expires, manufacturers other than the original developer have the freedom to produce generic versions of the product. These drugs are usually clinically equivalent to the original.

Can generic drugs have the same trade name as the original drug?

No. Though the chemical composition may be almost exactly alike, trademarks protect the original brand name, and generic brands must accommodate these regulations to avoid consumer confusion.

Does intellectual property protection increase drug prices?

Yes, it can potentially lead to an increase in drug prices. This is because patent exclusivity both delays cheaper versions of a drug from being made, as well as allows drug companies to have complete control over the pricing of their products.

How are manufacturing processes and drug formulas protected today?

One of the key ways drug formulas and their processes are protected is via trade secrets, which provide companies with a competitive advantage. These secrets do not need to be registered and can be protected for an unlimited amount of time, though there are some conditions for protection, including the following:

- The information must not be known to the general public

- The formula or process must have commercial value to be secret

- Reasonable steps must be taken by the information holder to keep it secret

Contact Oakwood Labs Today to Learn More

Have any additional questions? If so, reach out to our team at Oakwood Labs today. We look forward to answering your questions or discussing our services with you.

Parenteral drug administration is the delivery of medications or other substances through routes other than the digestive tract. The medication goes directly through the body while bypassing the gastrointestinal system, allowing rapid absorption into the bloodstream.

This form of treatment is used when immediate therapeutic effects are necessary, the patient is unable to take oral medication, or the medication is not offered in an oral form. Read on for insights about parenteral administration and the process for manufacturing drugs that use the application method.

Enteral vs. Parenteral Drug Administration

Enteral and parenteral are two common routes for administering medications and treatments to patients.

Parenteral drug administration delivers nutrients directly into the body without the digestive system through injections or infusions. It is used when there is a need for immediate therapeutic effects or when oral administration is not feasible. This method requires specialized training and equipment to ensure safe administration. Risk of infection or other complications may occur if it is not performed correctly.

Another method of drug administration is enteral. It delivers medications or nutrients through the gastrointestinal tract by way of oral administration or a feeding tube. This means that the digestive system must be fully functioning in order to absorb the medications or nutrients. Since it is the natural route for nutrient absorption, it is generally considered safer than parenteral drug administration. However, the absorption may be influenced by factors like gastric emptying, gastrointestinal mobility, other drugs, and even food. Additionally, the patient must be able to accept oral drugs.

Overall, parenteral administration is used when there needs to be immediate relief or a bypass of the digestive system, while enteral administration is employed when the digestive tract is functioning and able to absorb nutrients and medications. Therefore, when choosing whether to manufacture enteral or parenteral drugs, it is essential to fully understand the needs of your targeted demographic of patients to make an informed decision.

The Benefits of Parenteral Drug Administration

One of the main benefits of parenteral drugs is the fact that they offer very precise dosages. This is because the drugs are administered directly to the site for treatment, which means their absorption rate is greater than if they were to pass through the metabolism first.

Other benefits of parenteral drugs for patients who need a variety of therapeutical treatments include:

- Rapid action – Parenteral drug administration medications can be directed into the bloodstream, which results in a rapid delivery of the drug. They are absorbed quicker than medications with oral administration, resulting in immediate therapeutic effects that are extremely useful where quick relief is necessary.

- Predictable absorption – Parenteral drug absorption tends to be more predictable than oral administration, which is important for medications with small therapeutic windows.

- Reduced gastrointestinal irritation – Some drugs can cause irritation and damage to the gastrointestinal tract, which can cause a lot of discomfort to the patient. Parenteral administration doesn’t involve the digestive system which reduces these complications.

- Avoidance of first-pass metabolism – Drugs administered orally must pass through the liver before they can reach the targeted spot. When the drug is metabolized, its effectiveness can be reduced because less of the drug travels into the systemic circulation. However, parenteral administration bypasses this metabolization which can result in a greater proportion of the drug meeting the intended site.

Another benefit of parenteral administration is the improved patient compliance. Patients who experience side effects of oral medications and opt for parenteral drug administration could experience less discomfort when going through treatment. This means reduced nausea, vomiting, and difficulty swallowing, which can result in better adherence to therapy plans.

Methods of Parenteral Administration

There are many ways to administer parenteral drugs. Some are more popular than others, but the method highly depends on the needs of the patient.

Some of the most common methods of parenteral drug administration include:

- Intravenous – Delivered directly into the vein, which is the fastest and most direct route

- Intramuscular – Injected into a muscle, which allows for absorption over a longer period of time when compared to an IV

- Subcutaneous – Injected into the fatty tissue beneath the skin which is beneficial for medications that require slower and sustained absorption

However, the list does not stop here. Other administration methods include:

- Intraosseous – Delivered directly into bone marrow, which is common for emergency situations where IV access is limited or difficult

- Intradermal – Injected into the dermal layer of the skin, which is used for some allergy testing and certain vaccinations

- Intracardiac – Directed toward the heart which is useful for cardiac resuscitation procedures

- Intra-articular – Injected into a joint space which is commonly used to treat inflammatory joint conditions

While there are many avenues for parenteral administration, not all drugs can be delivered this way. While many of them can, there are certain exceptions for select medications, and some drugs have specific requirements or restrictions for parenteral drug administration. So, as a manufacturer, it is critical to develop clear instructions for delivery.

The Process of Manufacturing Parenteral Drugs

Since we manufacture pharmaceuticals, we wanted to touch upon the typical manufacturing process for parenteral drugs that ensures they are sterile and safe.

Here is a simple overview of the process:

- Develop the formulation using active pharmaceutical ingredients, excipients, and other components that will achieve the desired therapeutic effect.

- Create a sterile environment that is controlled. This typically involves the use of cleanrooms or isolators that are equipped with advanced air filtration or purification systems to ensure sterility.

- Weigh and mix the API, excipients, and the other components to ensure an even distribution.

- Sterilize the mixture to remove microorganisms. This step is crucial since the parenteral drugs are administered directly into the body. Sterilization can be done through filtration, autoclaving, or aseptic processing.

- Fill the sterile drug formulation into appropriate containers like vials and pre-filled syringes. This should be done under aseptic conditions to prevent any contamination. Then, the containers are sealed in a way that maintains the sterility of the drug.

- Label and package the formulation with information about the drug.

- Test samples from each batch to check the potency, purity, sterility, endotoxin levels, and more.

- Check the stability of the formulation to see the drug’s quality and efficacy over time.

- Submit applicable drug information to the FDA to ensure that it is ready for parenteral administration in hospitals, doctors’ offices, and more.

After this process is concluded, it is time for the drug to be shipped off so that it can be used in parenteral administration for patients.

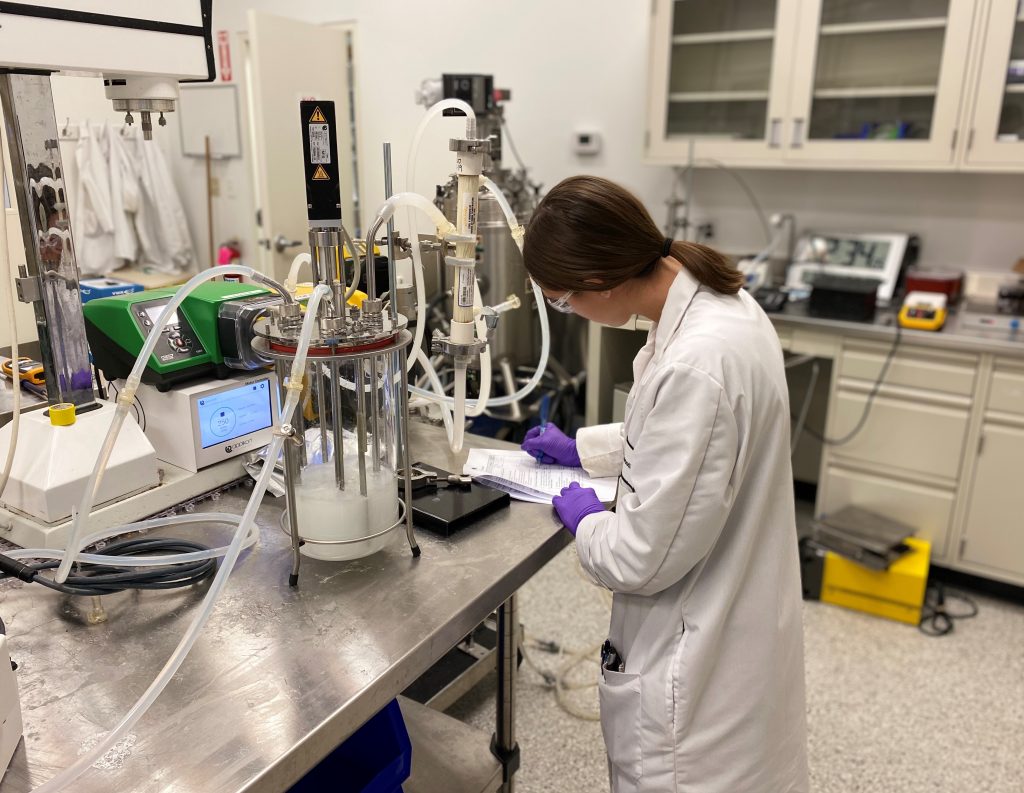

Oakwood Labs Is Your Destination for Manufacturing Parenteral Drugs

It is any manufacturer’s job to adhere to Good Manufacturing Practices (GMP) to ensure product safety and quality. We’re committed to doing so, and since our founding in 1997, Oakwood Labs has grown to become one of the prominent manufacturers of sustained-release parenteral products. We operate in an FDA-approved, aseptic facility, meaning we are ready to tackle your next manufacturing project.

Through our patented Chroniject™ and contract manufacturing services, we can help you treat more patients with the use of parenteral drug administration.

Contact Us Today for More Information

For more information on parenteral drug administration and its manufacturing processes, be sure to contact Oakwood Labs.

Quick Facts About Biologics in the Pharmaceutical Industry

- Biological medicines are carefully regulated by agencies like the FDA and EMA, requiring rigorous clinical and preclinical trials, ongoing safety monitoring, and strict manufacturing standards, including production in GMP facilities and detailed labeling for patient safety.

- Incorporation of biologics with sustained-release technology, such as microspheres, implants, hydrogels, and fusion proteins enables controlled, prolonged drug delivery, enhancing therapeutic effects and reducing dosing frequency for patients.

- Compared to traditional small-molecule drugs, biologics are larger, more complex molecules with targeted mechanisms of action and personalized treatment potential, but generally shorter stability and shelf-life due to their sensitivity to environmental factors.

Biologics are drugs produced using a living system, like microorganisms, plant cells, or animal cells. The particles used in biologics are made through complex processes and are at the center of a variety of products like vaccines, monoclonal antibodies, recombinant proteins, gene therapies, and beyond.

Biologics are reinventing the way we view the pharmaceutical landscape because they are innovative solutions that provide therapeutic benefits to patients with a wide range of diseases and conditions. Learn more about this fascinating technology and discover how it is being used to help provide relief to a variety of patients in our post.

The Origin of Biologics in Pharmaceuticals

The first use of biologics in medicine traces back to the late 19th and early 20th centuries. Emil von Behring was the first to make the discovery while working on a serum therapy for diphtheria. However, it was Paul Ehrlich’s work on the “magic bullet” that started the movement for the use of biologics in targeted drug delivery. Together, the work of von Behring and Ehrlich led to the development of vaccines that worked against infectious diseases, marking the earliest successes of biologics in medicine.

It is safe to say that a lot has evolved since the discovery of biologics in medicine, and regulation has played a key role. The use of biologics in medicine started to be regulated by the Food and Drug Administration (FDA) and European Medicines Agency (EMA) in the early 2000s. These organizations set specific guidelines in place to ensure any produced drugs are safe and transparency is maintained for patients.

Regulating Biological Medicine

The FDA and EMA oversee the approval for regulation of biological products. The approval process is rigorous to help ensure the safety, efficacy, and quality of each product released to the public. For this to happen, each biological medicine goes through both clinical and preclinical testing. The clinical trials include three phases of testing.

Once a biological drug is approved for use on the market, agencies continue to monitor the safety of it through surveillance programs. Adverse and other side effects are reported and evaluated. Products will be taken off the market if serious safety concerns arise. Additionally, there are thorough investigations conducted specifically for the use of biologics in the pediatric and geriatric populations.

Lastly, there are strict quality control measures in place to ensure consistency throughout the manufacturing process. Biologicals must be manufactured in a GMP facility. Additionally, there must be a label on the drug that describes product information like dosing, administration, potential side effects, and contraindications. Together, these factors work together to keep patients safe while encouraging the evolution of treatment for appropriate populations.

Using Biologicals in Pharmaceuticals to Provide Therapeutic Benefits to Patients

Following their discoveries, von Behring and Ehrlich truly started a movement when they began using biologicals in pharmaceuticals. Since these two found success back in the early 19th and 20th centuries, a variety of other discoveries have been made.

Here are some other astonishing biologic discoveries that have shifted the way that patients are treated:

- Recombinant DNA technology used the genetic engineering of bacteria to produce human proteins like the insulin growth hormone and revolutionized diabetes treatment

- Monoclonal antibodies were discovered, opening up new opportunities to prevent organ transplant rejection

- Growth hormones were developed to help children who had growth disorders

- Cytokines were understood on a deeper level which resulted in therapeutic treatment for immune disorders like asthma, rheumatoid arthritis, Lupus, Cohn’s Disease, and more

- Gene therapies like Kynriah can be used to treat certain types of cancer

- mRNA can be used in vaccine technology, such as with the COVID-19 vaccine

Combining Biological Medicine with Sustained Release Technology

Since Oakwood Labs uses sustained-release technology, it would be amiss to not look at biologics for this form of therapy. Biologics can be modified to achieve specific release patterns that enable controlled and sustained drug delivery in patients. This leads to reduced dosing and better therapeutic benefits for patients who need it.

Here are the main methods that incorporate the use of biologicals with sustained-release technology:

- Microspheres/nanoparticles – Biologics can be encapsulated within microspheres and nanoparticles that are made out of biocompatible materials. Then, these particles can be engineered to release the biologic over an extended period of time. The encapsulation is helpful for protecting the biologic from degradation and can be used to enhance stability.

- Implants – Biologic medicine can be encapsulated within implantable devices like biodegradable scaffolds. As the scaffold breaks down, it will slowly release the biologic which is useful for localized and long-lasting treatments.

- Hydrogels – Hydrogels are water-absorbing polymers that hold water and biologics. Gels can be designed to have sustained release qualities to maintain a consistent concentration of the therapeutic agent for extended periods of time.

- Fusion proteins – Engineering fusion proteins is done by combining a biologic with a carrier protein. The carrier protein helps extend the half-life of the biologic which creates a sustained release effect.

Benefits of Incorporating Biologics into Medicine

Using biologics in medicine has proven its success in countless ways across the industry. Biologics can benefit each patient in different ways, and this depends on what they are being treated for.

Here are just a few of the properties that biologics possess and why they are trusted to form new treatments:

- Targetable – Biologics can be targeted to reach specific molecules, cells, or even pathways, which encourages precise treatment while simultaneously reducing the risk of attacking healthy cells or tissues.

- Diverse – Effective therapeutic outcomes can be achieved for a wider audience since biologics can be personalized with a patient’s unique genetic makeup in mind.

- Innovative – Thanks to advancements in technology, biologics are used to treat diseases that were previously difficult to target with small-molecule drugs. Examples include autoimmune disorders, certain types of cancer, and rare genetic diseases.

Biologics in Pharmaceuticals vs. Small Molecule Drugs

From their composition to their manufacturing processes, there are a variety of ways that biologic medications differ from traditional small-molecule drugs.

- Composition – Biologics are large, complex molecules that are derived from living organisms. They are produced using biotechnical processes. Small-molecule drugs are chemically synthesized with a smaller-sized molecule. They have a defined number of atoms.

- Action course – Biologicals have highly specific mechanisms of action that allow them to target specific cells, proteins, and receptors. This makes them especially useful in precision medicine and targeted therapy treatments. However, small-molecule drugs have a tendency to interact with a wide range of molecules due to their small size and structure.

- Stability – Since biologics are sensitive to environmental factors like temperature and pH, their stability and shelf life are often shorter than those of small-molecule drugs.

Contact Us Today for More Information

Biologicals are at the forefront of biomedical research. With time, we can expect them to offer effective treatments for a variety of medical illnesses and conditions that have formerly been difficult to treat.

If you have any questions about biological medicines or the future of their impact in the world of pharmaceuticals, be sure to reach out to our team.

Summarizing the Role of Amino Acids in Pharmaceuticals

- Amino acids contribute to drug formulation by supporting matrix formation, enhancing solubility and stability, modulating drug release, and promoting biocompatibility.

- Different amino acids or combinations can be tailored to match the drug’s characteristics, desired release kinetics, and patient needs, which allows for customizable and effective pharmaceutical solutions.

- In addition to reduced dosing, these formulations provide prolonged action, targeted delivery, fewer side effects, and improved control over drug absorption, which enhances both treatment outcomes and patient experiences.

Amino acids have proven their capabilities in the pharmaceutical industry in a variety of ways. They can be used alone as nutritional supplements, synthesized to help form other products, or even built into drug delivery systems.

Since Oakwood Labs focuses on drug formulation, we wanted to explain the role of amino acids in pharmaceuticals, specifically addressing how they impact sustained-release injectables and provide therapeutic benefits to patients.

How Amino Acids Benefit Your Pharmaceutical Projects

Amino acids are used in the development and function of sustained-release injectables and pharmaceuticals because they help with matrix formulation, suspension, drug diffusion, and biocompatibility.

Different amino acids and combinations can be deployed to achieve specific therapeutic goals. With this in mind, the amino acids used will depend on factors like the drug that is being delivered, the intended release kinetics, and the compatibility of the overall formation.

Using amino acids in pharmaceuticals like sustained-release injectables assist with the following:

- Matrix formulation – The use of amino acids in sustained-release injectables can help form a matrix that is modified to perform long-acting therapy for the patient. The matrix encapsulates the active drug and helps control the rate at which it is released, making it ideal for less frequent doses and better patient compliance.

- Solubility – Solubility is needed in drug formulations because it leads to effective absorption. By enhancing the solubility of certain drugs, amino acids better maintain the composition of the drug and promote absorption into the body.

- Stability – Along with solubility, amino acids also protect the drug from degradation throughout the process of storage and release. Stabilization additionally helps increase drug effectiveness, especially when dealing with sustained-release applications.

- Modulation – Using amino acids in a sustained-release application can adjust the overall drug output to meet the demands of the patient. This means amino acids are capable of altering the diffusion characteristics of the drug being used within the formulation to better meet a patient’s therapeutic objectives.

- Biocompatibility – Amino acids used in pharmaceutical applications like sustained-release injectables can promote biocompatibility for medical applications. Biocompatibility means that the injectable will not interfere with any of the other cellular functions or compromise the patient’s wellness, and it is important because it increases safety, long-term tolerability, and regulatory compliance.

Benefits of Using Sustained-Release Pharmaceuticals

Sustained-release injectables and pharmaceuticals have gained popularity in recent years due to their variety of benefits. Since the drug remains active in the bloodstream over a period of time, sustained-release dosages offer prolonged therapeutic effects. This helps improve patient compliance and reduce the frequency of dosing.

Other advantages of sustained-release dosages include:

- Prolonged action of the medicaments

- Control over drug therapy

- Ability to modify the extent and rate of drug absorption

- Delivering API directly to the desired location

- Decreasing total amount of a drug, reducing local side effects

- Ability to modify the extent and rate of drug absorption

Work with Oakwood Labs on Your Next Project

If you are looking to incorporate amino acids into your pharmaceuticals, be sure to request help from the team at Oakwood Labs. We are a leading manufacturer of sustained-release pharmaceuticals and will work with you throughout the creation process. This includes proof of concept, feasibility studies, clinical trials, and finally the production of an FDA-approved commercial supply.

Additionally, our team has over 20 years of experience, which makes us a trusted and effective partner for global pharmaceutical firms of all sizes. See how we can incorporate amino acids into your sustained-release pharmaceuticals and beyond today.

Learn More About Using Amino Acids in Pharmaceuticals

The team at Oakwood Labs is ready to help you achieve high-quality results in your next project. Our quality assurance and validation practices will deliver the best solutions, regardless of the formulation needed.

For more information on using amino acids in sustained-release pharmaceuticals, be sure to contact us today.

Microspheres vs. Microcapsules: Key Takeaways

- Microspheres and microcapsules are both microparticles used in sustained-release injectable pharmaceuticals, but they have distinct structures. Microspheres are hollow with a solid outer casing, while microcapsules have a solid or liquid core enclosed in a shell-like coating.

- Microspheres, ranging from 1 μm to 1 mm in size, are made of polymers and can be delivered through various routes, including oral, parenteral, nasal, ophthalmic, and transdermal methods.

- Oakwood Labs has a patented microsphere technology, Chroniject™, which offers several advantages, including rapid formulation development using small-scale batches, easy scalability, compatibility with various molecules, and flexible release durations from one week to one year.

As you know, Oakwood Labs is a global leader in sustained release injectable pharmaceuticals. One of the key components of these drugs are microparticles, which are delivery systems for water-insoluble and sparingly water-soluble agents. Microparticles are split into microspheres and microcapsules.

Both of these play an important role in the pharmaceutical development process at Oakwood Labs. Learn more about microspheres vs. microcapsules.

What Are Microspheres?

Microspheres are small spherical particles that have a solid outer casing, are hollow, and do not contain fluid inside. These particles are made out of polymers and are used in drug delivery applications due to the high surface area, but low particle size. Their size ranges from 1 μm to 1 mm, making them effective for traveling within different areas throughout the body, which helps increase absorption rate and bioavailability.

Microspheres can be delivered through oral, parenteral, nasal, ophthalmic, and transdermal methods. They attach to proteins, peptides, antibodies, antigens and other small molecules to travel through the body and release at controlled rates.

Using microspheres in drug delivery has many benefits including release rates are tailored to specific applications (constant rate of delivery or rapid release), an increase in patient comfort and compliance by reducing the dosing frequency, and more.

What Are Microcapsules?

A microcapsule is also a small spherical particle, but its size is a little different, being 50 nm to 2 mm. The structure of a microcapsule is that of a membrane-enclosed core with a shell-like coating. Sometimes there are multiple cores within the coating. The core is composed of a drug constituent, stabilizers, or additives. The outside coating consists of an inert polymer, coloring agent, plasticizers, resins, waxes and lipids.

Microcapsules allow the core to be isolated from the outside environment and then released when desired. These microcapsules are used for sustained drug release, converting liquid drugs in a free-flowing powder, reducing toxicity and GI irritation, and for drugs that are sensitive to oxygen, moisture or light.

The Key Differences Between Microspheres and Microcapsules

The major difference between microspheres vs. microcapsules is the structure of the particle. As mentioned previously, microspheres have a solid casing and are hollow, while a microcapsule has a solid or liquid core in a shell-like coating.

The main reason for microencapsulation in pharmaceuticals is to protect drugs from environmental hazards like humidity, light, oxygen or heat. They also help controlled release within the patient and avoid too rapid of a release.

Microspheres are manufactured out of different types of polymers that when injected react within the patient to release a certain amount of the drug. While microspheres and microcapsules achieve similar goals for controlled drug release, their structures are what sets them apart.

Our Process for Manufacturing Microsphere Technology

At Oakwood Labs, our microsphere manufacturing capabilities have solved complex pharmaceutical industry challenges for more than 20 years. Our microsphere technology Chroniject™ is a patented, polymer-based injectable microsphere system for drug delivery. This technology is unmatched, and some of its major benefits include:

- Use of small-scale batches allow for rapidly developed formulations

- Formulations are easily scalable

- Process parameters are well-controlled

- Compatibility with peptides, small molecules, and proteins

- Excellent stability

- Flexible release durations ranging from one week to one year

Reach Out Today for More Information on Microcapsules and Microspheres

Our team is fully equipped and operates a staffed research and development facility specifically created to manufacture sustained release injectables. Oakwood Labs is committed to developing products to provide therapeutic benefits to patients.

If you are interested in learning more about microspheres vs. microcapsules for drug delivery, contact us at Oakwood Labs today.

Key Takeaways of Repurposing Drugs

- Time and cost savings – Traditional drug development can take 12–15 years and cost $1–3 billion. Repurposing drugs can significantly cut down both the time and cost by skipping or abbreviating early clinical trial phases.

- Higher probability of success – Since repurposed drugs have existing human data, adverse effects and toxicity profiles are often better understood. This tends to lead to higher approval rates compared to brand-new compounds.

- Broad applications – Repurposing is particularly useful for rare diseases or diseases with few treatment options. In the oncology space, non-cancer drugs are being tested for viability as cancer therapies because many diseases share common molecular pathways.

- Institutional capacity matters – Organizations like Oakwood Labs, with expertise in development, manufacturing, and regulatory compliance, are well-positioned to support the drug repurposing market through formulation development, scale-up, and manufacturing.

A Brief Introduction to Repurposing Drugs

The medical field is always searching for new opportunities to help treat patients, and one technique that provides various advantages is drug repurposing, also known as drug positioning or drug repositioning. This innovative technique involves exploring new medical uses for existing drugs.

At Oakwood Labs, we are a leader in the pharmaceutical industry and drug repurposing market, solving difficult challenges that arise from developing pharmaceutical injectables. Similar to the goals of drug repurposing, we strive to develop products that provide therapeutic benefits to patients and practical benefits to medical operations.

Using Repurposed Drugs for Cancer

Focusing specifically on oncology and the effort to find new treatments, repurposed drugs for cancer have become an attractive option, with some non-cancer drugs being examined for their possible efficacy. Many unrelated diseases share common molecular traits, making repurposing possible. It also opens the door for different diseases to respond to the same drug.

Traditionally, bringing a new drug on the market would take 12 to 15 years and would require a large budget of 1 to 3 billion dollars. By choosing the approach of drug repositioning, you’ll reap benefits such as:

- Cutting costs surrounding research and development

- Reducing the timeline of development, because if the drug has already been safely administered to humans, you could skip Phase 1 of clinical trials

- Higher approval rates

- Comprehensive information is available on pharmacology dose, possible toxicity, and more

The Role of Drug Repositioning in the Greater Pharmaceutical Industry

Pharmaceutical companies continue to evolve, shaping the future of drug development by finding innovative solutions, such as drug positioning. With many rare diseases in the world having few approved treatment options, repositioning of drugs has become an effective strategy.

Using the repurposed drug strategy for such cases, facilities can minimize the knowledge gap that occurs when running a clinical trial. By understanding more about the drug, such as how it reacts in the body, organizations can also help speed up the process.

Since drugs are chemicals that change the biochemical pathways in our cells, it’s common for them to have an effect on more than one pathway. In drug repositioning, we can take advantage of those different effects to provide solutions to diverse medical conditions.

Oakwood Labs, a Leading Manufacturer in the Drug Repurposing Market

With over twenty years of industry expertise, we have proven ourselves to be an effective partner to global pharmaceutical firms of various sizes. Whether you are in the early development stage or are looking to scale up an existing formulation, we are ready to help.

Oakwood Labs strives to achieve milestones within set deadlines, provide transparent communication, adapt to change, and offer our expertise throughout the entire development process. We have everything you need, from support to our FDA-approved cGMP manufacturing facility, all to help enhance our development capabilities and aptitude for repurposing drugs.

Our facility offers a variety of contract manufacturing services, including:

- Commercial products for use in humans or for veterinary use

- Phase I, Phase II, or Phase III clinical trial material

- Sterile liquids, sterile lyophilized parenteral, suspensions, microspheres, and others

- Small-volume injectables

- Class III and IV DEA controlled substances

- Vials with lyophilized or plug stoppers, with both 13 mm and 20 mm openings

Contact Our Team

At Oakwood Labs, we are ready to use our technology and expertise to tailor solutions to your project’s needs. If you’re interested in drug repurposing and would like to discuss options with us, contact our team today.

We are ready to support all phases of long-acting injectable development and help you with your next project.

Key Takeaways About the Disadvantages of Extended-Release Tablets

- Sustained-release injectables maintain more stable plasma levels over time, reducing peaks and lows, and lowering side-effect risks compared to sustained-release capsules

- Injectable formats avoid dose dumping, which can be a serious risk when using many sustained-release medications

- Injectables improve patient adherence by eliminating the need for daily dosing and minimizing missed doses, which can be a challenge with sustained-released drugs that are taken orally

- Injectable delivery under controlled administration reduces overdose risk and misuse potential, which can be among the disadvantages of extended-release tablets

About Sustained-Release Medication

Sustained-release injectables provide a solution for those that require long-term treatment, or in cases where patients can’t swallow sustained-release tablets or capsules. Also, depending on the drug, certain tablets cannot be crushed, making injectables the preferred option as well.

Oakwood Labs focuses on long-acting injectable development since these medication delivery methods can reduce the number of injections needed, target specific anatomical areas, and help improve patient compliance. By choosing injectables over sustained-release capsules, you’ll achieve the quality and efficacy you’re seeking.

What Are Sustained-Release Tablets?

Disadvantages of Choosing a Tablet Over an Injectable

While they do offer some benefits, there are distinct disadvantages of extended-release tablets compared to injectables. Tablets have a higher risk of dosage issues, often known as dose dumping. This is when large amounts of a drug are quickly released, and a toxic quantity is introduced into systemic circulation. These capsules are also often quite large in size, which may cause issues in ingestion or transit through the digestive system.

Why Sustained-Release Injectables Are Beneficial

Sustained-release injectables are often the preferred method among clinical professionals due to the convenience and effectiveness they offer. While there are various types of injectables, depending on the medication they are utilized for the effects can last anywhere from two to twelve weeks with one dose. This provides a practical option for those having trouble taking medication on a daily basis.

By choosing injectables in place of sustained-release capsules, you will help improve the lives and routines of patients in the following ways:

- Safety – When administered by medical personnel, sustained-release injectables can help guarantee safety for your patients. Through regulated injections, you reduce the risk of accidental or deliberate overdose.

- Regularity – Patients who receive injectables need to show up for more appointments, creating regular interactions between them and their medical team. This results in a solid routine and an increase in social interactions.

- Stability – Sustained-release injectables help by treating patients with more stable plasma concentrations compared to sustained-release tablets or oral medications. It also lessens the frequency of having peak plasma levels, which can result in lesser side effects for the patient. Also, for those prone to hospital visits, relapse frequency and rehospitalization rates are decreased.

- Reduced accountability – In order to see the best results with medications, it’s important for patients to take them every day. With long-acting injectables, patients no longer need to keep track of daily dosing needs.

Choose Oakwood Labs as Your Source for Sustained-Release Pharmaceuticals

At Oakwood Labs, we understand how essential a partnership is when developing a sustained-release drug from concept to commercialization. With our state-of-the-art technology and personnel, we’ve been able to solve common challenges involved with developing sustained-release injectables such as formulation development, GMB manufacturing under rigorous quality systems, scaling up, and process controls.

As a specialty pharmaceutical company, we are here to help in development as well as scaling up an existing formulation. We support all phases of long-acting injectable (LAI) development, working with you through proof of concept to clinical trial material, all the way up to FDA-approved commercial supply.

By choosing Oakwood Labs as your effective partner, you’ll gain services and benefits such as:

- A strong focus on project management and communication

- Tailored release profile from weeks to one year

- Contract manufacturing services

- ChronijectTM, our patented injectable microsphere technology

- A track record of success for taking projects through every process stage

- Efficient and stringent process controls

- R&D formulation development

- Demonstrated lot-to-lot reproducibility with proven scale-up success

Contact Us to Learn More About Sustained-Release Injectables

Our special pharmaceutical company is ready to help ensure you meet your requirements and expectations for sustained-release injectables. If you’re wanting to learn more about how Oakwood Labs can provide solutions to your company, reach out to our team today.

Additional Resources on Sustained-Release Injectable Development

Medications are classified and categorized in many ways including when it comes to distribution methods, dosage, intent, and more. For the purposes of this post, we are going to focus on the rate at which medications are released in the body to serve their intended function.

The time it takes for a drug to run its course will impact all of the characteristics mentioned above, so we’ll look at extended-release medication and modified-release medication and how it applies to drug delivery.

What Is the Difference Between Immediate-Release Drugs and Extended-Release Drugs?

Immediate-Release Drugs

For the purposes of comparison and to fully understand the role of extended-release medications, we’ll start by acknowledging the most common oral dosage for medication, which is immediate release. Any medications classified as immediate release, or IR, go to work very quickly and for a short period of time.

Modified-Release Drugs

As part of an effort to administer medications more conveniently and provide worthwhile options for patients, modified-release medications began appearing on the market. These medications were developed to extend and/or delay their effects to better aid the patient. Their design often means that a patient is required to take medication less frequently, which in many cases is majorly beneficial to their lifestyle.

Modified-release drugs, also known as extended-release drugs or slow-release drugs, are designed to last longer in your body. For example, someone administered an extended-release medication may only need to take one to two doses as opposed to three to four doses of an IR medication. From a physiological standpoint, these medications are absorbed much slower by the patient and do not start breaking down until they reach a certain area of the body.

What Purposes Do Slow-Release Drugs Serve and How Can Oakwood Labs Help?

As mentioned above, modified-release drugs require less frequent doses while still delivering the same medicinal benefits as their counterpart IR medications. This can be quite beneficial when it comes to an individual who has trouble taking medication on a set schedule or more than once a day.

One type of extend-release medication that is frequently used is long-acting injectables. Oakwood Labs is a leader in the development and manufacturing of these extended-release injectables, and some benefits of this type of drug administration include:

- Fewer injections needed over a determined period of time

- Ability to target precise areas of the body

- Improved patient compliance

- Help in preventing drug abuse

Our team has over 20 years of drug encapsulation experience and can work closely with you in developing long-acting injectables for your needs. Visit our homepage to learn about everything we can provide.

Contact Oakwood Labs for Extended-Release Medications

Oakwood Labs has been working in pharmaceutical development for over two decades and has a team of dedicated scientists ready to help your business from concept to finished product.

If you are interested in working with us or would like to learn more about slow-release medications, contact our team today!

It is important to note that “extended-release pharmaceuticals” is an umbrella term for both sustained- and controlled-release pharmaceuticals. These drugs are part of a series called modified-release dosage forms, which refers to the medication’s time-release technology.

Typically, the drugs you ingest are immediate release, which means they are instantly activated when they are ingested. However, extended-release, sustained-release, and controlled-release drugs are modified pharmaceuticals designed to release at a delayed or slower rate to change how and when the drug hits your system.

A Breakdown on Extended-Release Pharmaceuticals

Extended-release drugs were created to offset the side effects that come with traditional, immediate-release drugs. IR drugs are designed to release a spike of medication into the bloodstream that then tapers off. Because of this, extended-release pharmaceuticals offset that spike of medication to provide a steadier amount of medication into the body.

Controlled-Release Medication

- These are medications that are labeled with “CR” at the end of their medical names

- CR drugs can release active ingredients at a very specific rate to ensure there is a constant medication flow in the body for a specific period of time

- Due to their medication-regulating abilities, fewer doses are required throughout the day

Sustained-Release Medication

- These are medications that are labeled with “SR” at the end of their medical names

- SR tablets or capsules prolong the medication’s release to dole out the benefits of the medication over a longer time period

- Although the medication is released over a longer period, the medication levels do not remain constant while in the body

Extended-Release Injectables from Oakwood Labs

Here at Oakwood Labs, we are your source for extended-release injectables. With over 20 years of drug encapsulation experience, we have patented technology to control particle size, customize release durations, and minimize residual solvents.

Our team of professionals has the ability to perform research and develop specially formulated extended-release injectable medications for our customers’ specific needs. Some benefits of our extended-release injectables include:

- Reducing the number of injections needed

- Ability to target specific anatomical areas

- Improved patient compliance

- Helping to prevent drug abuse

Extended-release drugs make it simpler for individuals to take medications on a regular basis, as these drugs are easier for the body to tolerate in comparison to immediate-release pharmaceuticals. Due to their modified composition, fewer doses are required, making it simpler to stick to a medication schedule.

Overall, extended-release pharmaceuticals allow your body to feel the effects of the specific medication over a longer time period, but via fewer doses. Understanding the specifics of extended-release drugs is important so you can predict how your body will react.

Contact Us for Extended-Release Drugs

Oakwood Labs is the best source for long-acting injectable manufacturing. Not only are we an industry leader in injectable pharmaceutical development, but we are very committed to quality and customer satisfaction.

If you have any questions on extended-release injectables, contact us today for additional information!

Related Blog Posts

Applications for Microparticles in the Pharmaceutical Industry

Microparticles are generally made up of proteins or synthetic polymeric materials. They can be found in sizes ranging from 1 to 1000 mm, making them ideal for many different applications, including vaccines and other treatments. The following applications describe how they ease patients in need of relief and help the industry:

- When found in small sizes, microparticles are used for inhalation delivery because they are easily dispersed and aerodynamic, allowing them to travel to the deeper regions of the lungs.

- In addition to their role in transferring treatment to deep regions to the body, microparticles play an important role in the treatment and diagnosis of various cancers, including brain cancer, lung cancer, colon cancer, breast cancer, and ovarian cancer.

- Microparticles used in drug delivery have also shown promising results in reducing the treatment time of tuberculosis since they enhance the efficacy of the antibiotics delivered.

Reasons to Use Microparticles in Drug Delivery

Since they were first introduced to the medical field, microparticles have improved the efficiency of different medical treatments. The following advantages describe the benefits of using microparticles in drug delivery:

- Protective coating – Using microparticles supplies bioactive drugs, proteins, and small molecules with protection from degradation. This allows the microparticles to travel freely to their intended destination.

- Controlled release – Microparticles have the ability to effectively achieve a controlled release rate of encapsulated drugs, whether over a period of hours, weeks, or months. This can help in treating patients who forget to take their medication or those who do not want to attend as many appointments.

- Effective for various applications – Microparticles are effective because they can be used for a variety of drugs and can therefore be used in a variety of treatments. For example, they help cancer patients by reducing the number of chemotherapeutic drugs used in patients, reducing the side effects that the patient would otherwise experience.

How Oakwood Labs Can Help in Developing Effective Delivery of Microparticles

At Oakwood Labs, we specialize in formulating microparticles for pharmaceuticals. From the duration of release to the needle size, we work to determine the optimal product characteristics for your project. Other factors that we consider for your project include the following:

- Active pharmaceutical ingredient (API)

- Particle size

- Vial size

- Appropriate solvent system

- Selection of polymer

- Stable state levels

- Method of administration

- Drug load

Our Process for Incorporating Microparticles in Drug Delivery

After we determine the proper characteristics for your microparticle drug delivery, we begin the process of a feasibility study which will determine if the target profile is attainable with our technology. This process includes the following:

- Pre-formulation activities – Pre-formulation activities are used to develop the best approach for the production of microparticles.

- Completing feasibility formulations – The next step is to complete feasibility batches on a small scale. This data is later used to determine the microparticle weight, size, flow rate, and other factors.

- Finalizing reports and choosing formulations for testing – Our team will compile all of the appropriate data and results to form a summary of the microparticle After this, we will provide recommendations for candidate formulations that will be tested on animals. For the use of microparticles in pharmaceuticals and beyond, animal testing is outsourced.

- Further modification and scaling up – After animal testing, we determine the capability of the in vitro release test and use this in situations where further modification is necessary. At this point, the microparticle drug delivery system is ready to begin the process of scaling up.

Start the Process of Using Microparticles in Drug Delivery Today

When you are ready to include microparticles in your pharmaceuticals, be sure to work with a team that carries over 20 years of experience working in an aseptic, FDA-approved manufacturing facility.

Contact us today to learn more.