Category Archives: News

Nanoencapsulation is an expanding area of scientific research and development that impacts industries ranging from cosmetics to food production to pharmaceuticals. This area of nanoscience enables the controlled release of nutrients within the body for a specified location and duration, allowing nanoparticle drug delivery to supply a wealth of benefits.

The Oakwood Labs team is comprised of experts in developing long-acting injectables for diverse purposes, and that includes our work with nanoparticle encapsulation. Read on to learn about the benefits of nanoencapsulation in long-acting injectables and everything Oakwood Labs can provide.

About Nanoparticle Encapsulation

Encapsulation is the process of entrapping a material within another material, creating particles of variable sizes. These particles can be measured in millimeters, micrometers (denoted as microencapsulation), and nanometers (denoted as nanoencapsulation).

These particles are referred to as nanocarriers, or NCs, and they deliver an array of benefits for organizations, medical professionals, and patients alike.

Advantages of Encapsulation for Nanoparticles and Their Use in Long-Acting Injectables

Using nanoencapsulation in drug delivery can offer a range of benefits, including:

- Targeted delivery and bioavailability for patients suffering from a range of conditions

- Controlled release of medications that aid patients over longer periods

- Reduced systemic toxicity that can be associated with certain drugs due to efficient loading of drug molecules within nanocarriers

- Increased accumulation of a distributed drug at the distribution site of choice via targeted nanocarriers

- Increased efficacy of therapeutic agents and their targeting

- Prevention of premature degradation within the patient’s body and prolonged presence within blood and cells

- Nanocarriers of variable sizes can be created using distinct matrices, which can impact their effectiveness against biological barriers and their in vivo performance

- Reduced number of injections needed for a patient, which can make medication distribution easier and patients more compliant

- Prevention of drug abuse as excessive amounts of a drug will not need to be distributed to patients

The Oakwood Labs Chroniject™ Approach for Nanoencapsulation

Our long-acting injectable development at Oakwood Labs uses our technology platform Chroniject™, a patented polymer-based injectable microsphere system for nanoparticle drug delivery. This system allows us to:

- Provide drug release durations of 1 week to 1 year

- Distribute medications via 18- to 23-gauge needles

- Reconstitute products immediately via sterile water

- Provide proven drug stability and content uniformity

- Supply solutions free of foreign particulate matter

- Fulfill formulations aseptically and terminally sterilized if feasible

- Use microsphere-based, biodegradable polymers such as PLA, PLGA, and other polymers with demonstrated low toxicity, and sourced from multiple suppliers

Other Services from Oakwood Labs

At Oakwood Labs we’re industry leaders in sustained-release drug delivery, and that extends beyond our work in encapsulation for nanoparticles. We have over 25 years of experience in the field, and our team supplies full-service support, from initial feasibility studies to FDA-approved commercial supply.

We proudly offer a diverse array of services in the development and manufacturing of sustained-release products, including:

- Feasibility program

- Formulation optimization and scale-up

- Analytical and stability testing

- GMP aseptic manufacturing

- Contract manufacturing

Contact Us for Nanoencapsulation in Long-Acting Injectables

If your operations require nanoparticle encapsulation, the Oakwood Labs team is ready to assist. Contact us today to discuss your project.

The pharmaceutical industry harbors a vast range of key facts and significant data that can be beneficial to individuals and companies in the field. With the pharmaceutical market on a continuous rise in terms of revenue, innovation, and research, it’s important to stay up to date on current trends.

That’s why our team has compiled a list of 40+ statistics for your review, so you can learn more about the thriving pharmaceutical sector.

General Pharmaceutical Industry Trends

- New modalities, like cell and gene therapy, have increased from 11% to 21% of the drug development pipeline (McKinsey & Company)

- Based on pharmaceutical sales, the top therapeutic areas in the pharma industry are antidiabetics, immunology, oncologics, HIV antivirals, and respiratory (Statista)

- Research and development spending reached more than 300 billion dollars in the United States in 2023 (Statista)

- In 2023, biotechnology contributed to 40% of global pharmaceutical sales (Statista)

- The process of developing a new drug costs around 2.6 billion dollars in the USA, with the drug taking an average of 15 years to develop (Statista)

- The Pharmaceutical Research and Manufacturers of America trade group spends 21% of their revenue on research and development (Statista)

- PhRMA member companies spent 96 billion dollars in the USA on research and development in 2023 (Statista)

- In 2023, more than 5,500 pharmaceutical companies were conducting active research and development (Statista)

- More than 21,000 drugs were in the research and development phases in 2023 due to COVID-19 responses (Statista)

- Pfizer was the top U.S. company to develop new drugs in 2024 (Statista)

Statistics About the Pharmaceutical Market

- The total global pharmaceutical market in 2023 was estimated at around $1.6 trillion (Statistica)

- Compared to 2022, the total global pharmaceutical market increased by over 100 billion dollars in 2023 (Statistica)

- The United States accounts for nearly 40% of the world’s pharmaceutical market (National Library of Medicine)

- As of 2023, the top 5 largest pharmaceutical companies were Eli Lilly ($578.3B), Novo Nordisk ($452.8B), Johnson & Johnson ($377.7B), Merck ($263.9B), and AbbVie ($261.2B) (Visual Capitalist)

- Approximately $60 billion is spent collectively by the top 20 pharmaceutical companies each year for drug development (McKinsey & Company)

- The United States accounts for roughly 50% of global pharmaceutical sales revenue (PharmaNewsIntelligence)

- The pharmaceutical market in the United States is expected to surpass $1 trillion by the year 2030 (American Pharmaceutical Review)

- The biopharmaceutical market is expected to reach nearly $517 billion in 2024, and reach up to almost $762 billion by 2029 (Modor Intelligence)

- From 2024 to 2028, the pharmaceutical market is projected to experience an increased annual growth rate of 5.96% (Statistica)

- By 2027, the total global spending on medicine is projected to reach $1.92 trillion (Statistica)

- Currently, the United States is looking for an increased demand for personalized medicine and more targeted therapies (Statistica)

- In 2024, the United States gained more than 760 billion dollars in revenue from the pharmaceutical market (Statista)

- The United States accounted for 52% of global sales in the global pharmaceutical sector in 2024 (Statista)

A Career in the Pharmaceutical Industry: Noteworthy Statistics

- 56.8% of pharmacists in the United States are women and 43.2% of pharmacists are men (Zippia)

- Approximately 1.3 million people are employed in the pharmaceutical industry in the United States (U.S. Bureau of Labor Statistics)

- The average age of a pharmacist is 41 years old (Zippia)

- 91% of graduated pharmacists are known to work in the private sector (NIH)

- The average salary of a pharmacist is $118,968 as of 2024 (Zippia)

- The highest paying state for pharmacists is California, where the average yearly salary is $161,597 (Zippia)

- For every dollar that a man makes as a pharmacist, a woman makes approximately 98¢ (Zippia)

- The employment for pharmacists is expected to grow by 3% from 2022 to 2032 (U.S. Bureau of Labor Statistics)

- Over the decade, there is said to be 13,400 openings for pharmacists projected each year (U.S. Bureau of Labor Statistics)

- There has been a 20% increase in the demand for STEM-related jobs, making it difficult for the pharma industry to recruit technical talent (McKinsey & Company)

Statistics on Popular Prescription Drugs

- According to the Centers for Medicare & Medicaid Services (CMS), out-of-pocket drug spending is projected to peak in 2023 at $52.5 billion (Peterson-KFF)

- As of July of 2023, 25% of adults who take prescription drugs report difficulty in affording their medication (Peterson-KFF)

- There are more than 32,000 generic drugs that are approved by the FDA as of 2022 (FDA)

- In the United States, 91% of prescriptions are filled as generic drugs (FDA)

- Nationwide, the total spending on prescription drugs increased from $30 billion in 1980 to $335 billion in 2018 (Congressional Budget Office)

- Though the top 10% of drugs by price account for less than 1% of all prescriptions, they make up 15% of the retail spending and anywhere from 20% to 25% of the nonretail spending (ASPE)

- In 2020, around 6.3 billion prescriptions were dispensed in the United States (Statistica)

Oakwood Labs: Innovator of Sustained Release Drugs for the Pharmaceutical Sector

As seen in these compelling pharma market insights, it’s clear that the pharmaceutical industry is continuing to expand and develop, providing great value for both patients and business alike. Oakwood Labs plays an important role in this growth as a leader in the design and development of sustained-release drugs.

By using Chroniject™ technology, we developed a process where small molecules, peptides, and proteins can be injected and released over weeks, months, or years. This technology supports innovative solutions and has contributed to the success of the pharma industry.

With over 25 years of experience, we’ve helped bring drugs to the pharmaceutical market that enhance patient care and greatly benefit organizations. We also work with a wide range of clients, supplying services such as:

- Analytical and stability testing

- GMP aseptic manufacturing

- Feasibility program

- Formulation optimization and scale-up

- Contract manufacturing

By staying up to date on current pharma market insights, Oakwood Labs can help deliver the pharmaceutical solutions you’re looking for.

Contact Oakwood Labs for More Information

Oakwood Labs is a global provider of sustained-release pharmaceuticals and other medical services. Please contact our team of experts today for more information about all we can provide, as we look forward to answering any inquiries you have.

The team at Oakwood Labs has made it our mission to develop long-acting injectables to treat various diseases and disorders. This includes ongoing work with drugs to treat acromegaly and carcinoid tumors, both rare diseases that affect millions of people globally. Read on to learn more about the strides we’ve taken within endocrinology, and the broader healthcare sector.

The History of Acromegaly and Carcinoid Tumor Drug Development

Though carcinoid syndrome was first described by Thorson and colleagues in 1954, Pierre Marie discovered acromegaly years prior in 1886. At these times, there were no acromegaly and carcinoid tumor pharmaceuticals to reduce the size of malignant or benign growths, so surgical removal of a tumor was incredibly common.

Then, in the 1970s, dopamine agonists, such as bromocriptine and cabergoline, were introduced as treatment options to control tumor growth for acromegaly and carcinoid syndrome. However, the treatment came with a range of side effects, such as nausea, dizziness, and constipation, to name a few, so they are not used as standalone options for treatment today.

The Current State of These Pharmaceuticals

Numerous strides have been made within the healthcare sector since the early stages of acromegaly and carcinoid tumor drug development. For example, as of June 2020, the FDA has approved oral octreotide capsules as one of the first long-term maintenance treatments for acromegaly. This alternative is a viable solution for individuals who have responded to and tolerated treatment with injectable SRLs.

Along with more recent trials and discoveries, several targeted drugs are used to treat these diseases and manage their symptoms, with Sandostatin being one of the most common. These synthetic acromegaly and carcinoid pharmaceuticals are designed to mimic the body’s natural hormone, somatostatin, which, in turn, prevents the body from producing too many growth hormones and serotonin.

What Oakwood Labs Is Developing Internally for Acromegaly and Carcinoid Tumor Treatment

Oakwood Labs has successfully manufactured and scaled up formulations focused on treating acromegaly and carcinoid tumors. The daily injections initially used for these conditions have been largely replaced by Sandostatin LAR, a one-month LAI product. Plus, our two-month formulations further reduce the number of injections and office visits patients experience by 50%, which can also help with enhancing patient compliance.

Additionally, Oakwood Labs currently has two endocrinology programs that are focused on creating pharmaceuticals to treat acromegaly and carcinoid tumors. Project Treestar is designed to specifically treat acromegaly and cancer-related nausea, while Project Lunar is looking to help those with type 2 diabetes.

Partnership Opportunities

Oakwood Labs is seeking an external partner to help further develop our endocrinology program. Just some of the key responsibilities include:

- Funding the ongoing development activities

- Overseeing phase 1-3 of clinical trials

- Contributing to registration and commercialization efforts

If you’re interested in pursuing this opportunity, please reach out to our team directly for more information. We would be happy to supply the partner with additional information about the market opportunity, estimated financial projections, and development work to date.

FAQs About LAIs for Acromegaly and Carcinoid Tumor Treatment

What are the major benefits of an LAI in treatments for acromegaly, carcinoid tumors, and more?

When developing drugs for treating acromegaly and carcinoid tumors, know that long-acting injectables are effective for blocking the production of excess blood levels of growth hormone (GF) and reducing the insulin growth factor-1 (IGF-1) levels in acromegaly patients. This is helpful for individuals who cannot be treated with other methods, such as surgical intervention.

Sandostatin acts as a somatostatin analogue, mimicking a naturally occurring hormone that helps regulate hormone release from the tumor cells. This aids in the treatment of carcinoid tumors.

What are the current barriers to an LAI entering this particular space?

The barriers to entry for the LAI space are very high. You need to have a proven technology capable of delivering the right amount of the drug within a given therapeutic window. You also need an FDA-approved GMP facility to manufacture the product. Finally, you need a high level of expertise to understand, develop, and validate the process.

Oakwood has all these capabilities, along with over 25 years of expertise within the field.

Contact Our Team of Experts Today

If you have any questions regarding the process of developing pharmaceuticals for treating acromegaly and carcinoid tumors, or our work in the endocrinology space, please reach out to our team of experts today. And if you’re looking for a position within our partnership program, contact us directly, as we look forward to hearing from you.

Joint pain affects many people around the world, creating problems with everyday tasks, causing discomfort, and lessening their quality of life. Fortunately, advances in medicine have led to relief for those who suffer from a variety of conditions that result in joint pain, with long-acting injectables being an efficient method of delivery.

At Oakwood Labs, we’re a leader long-acting injectable development, putting our proven methodologies to work in drugs to treat joint pain. Read on to learn more about joint pain drug development and how the Oakwood Labs team can supply exactly what your operations need.

The History and Use of Long-Acting Injectables for Joint Pain Pharmaceuticals

Long-acting injectables were created in the 1950s to aid patients suffering from mental health conditions such as schizophrenia. As procedures evolved and new developments arose in the ensuing decades, the treatment of other conditions, including those centered more on the total body rather than just the mind, began to emerge. This includes using long-acting injectables to administer drugs for treating joint pain in knees, elbows, shoulders, and other problem areas.

Some of the common conditions that are suited for long-acting injectable medication distribution include:

- Osteoarthritis

- Rheumatoid arthritis

- Bursitis

- Tendonitis

- Psoriatic arthritis

Meanwhile, there are a range of medication types that may be distributed. These can include osteoarthritis pharmaceuticals, rheumatoid arthritis pharmaceuticals, and other forms, with specific injections containing:

- Corticosteroids

- Hyaluronic acid

- Platelet-rich plasma

- Additional formulations

Key Benefits of Long-Acting Pharmaceutical Drugs to Treat Joint Pain

Long-acting injectables, sometimes referred to as extended-release drugs or “ER drugs,” help to provide ongoing pain relief to patients who are suffering from an array of conditions. The result is a better quality of life, better pain management, increased mobility, and fewer dosages. Other benefits of these pharmaceuticals for treating joint pain include:

- Fewer side effects – Using long-acting injectable pharmaceuticals to treat joint pain can result in fewer side effects for patients because they will receive less frequent dosages than with immediate-release approaches. The reduced side effects are also facilitated by patients receiving lower peak concentrations of the given drug.

- Improved patient compliance – Since long-acting joint pain pharmaceuticals necessitate fewer doses, patients who take them are more likely to follow the plan put in place by their healthcare professionals. This results in improved pain management and happier patients.

- Reduced pain level fluctuations – Patients who take immediate-release drugs may notice a fluctuation in pain levels for their joint issues, but long-acting injectables lessen this experience, offering a more stable and controlled release that manages pain.

Our Abilities in Joint Pain Drug Development

The Oakwood Labs team has been proud to tackle projects for osteoarthritis drug development and rheumatoid arthritis drug development, providing long-acting injectables with a release duration of three months.

Our team specializes in developing pharmaceuticals that treat joint pain and can assist with developing formulations, scaling up the manufacturing process, and manufacturing clinical and commercial quantities under GMPs.

We find that long-acting injectables are ideal for use with pharmaceuticals for treating joint pain because joint pain often emanates from a specific bodily area and high concentrations of a drug can be administered without resulting in systemic exposure. This, and the potential for disease-modifying results, are yet more benefits to the LAI approach.

Our Work with LAI Formulations

In terms of our work, Oakwood has developed a 3-month LAI formulation of meloxicam. Meloxicam is one of the more potent NSAIDs, which enables targeted release in the intra-articular space, and thus avoids the systemic side effects of NSAIDs. Due to the high potency of meloxicam, a smaller injection volume is possible.

Challenges We Have Faced

One of the current barriers to entering this particular space is the difficulty of developing the proper formulation. Microspheres are preferable to gels that solidify after injection due to the mechanics of the joint and intra-articular space. Microspheres should be greater than 20 microns to avoid macrophages attacking them. Work with our team of LAI experts to develop the right formulation.

Partner with Us on Drugs to Treat Joint Pain

Oakwood Labs is actively looking to partner with interested organizations for co-development of programs such as those focused on treating joint pain. Be sure to visit our partnership page for more information on our approach and all areas we focus on. We would love to work with you to bring new drugs to market.

Have Questions About Pharmaceuticals to Treat Joint Pain? Contact Us

Reach out to the team at Oakwood Labs today and we can discuss our methodologies, facilities, previous projects, and more. We look forward to hearing from you.

At Oakwood Labs, we’re proud to contribute to the development of cancer pharmaceuticals through our continuous work manufacturing long-acting injectables (LAIs). That’s why we’ve compiled an informational guide showcasing our ongoing work in the healthcare field, as well as the numerous benefits of LAIs for oncology treatment.

Advantages of Long-Acting Injectables to Treat Cancer

There are numerous advantages to the use of LAIs as pharmaceuticals to treat cancer. To start, Bruton tyrosine kinase (BTK) inhibitors are established standards of care in multiple B-cell malignancies including chronic lymphocytic leukemia, mantle cell lymphoma, and Waldenstrom macroglobulinemia. LAI formulations of BTK inhibitors offer certain advantages in terms of pharmacokinetics (PK) and patient adherence. For example, ibrutinib (Imbruvica) has a very short half-life of 4-6 hours. Hence, relatively large doses of the oral form are required to target plasma levels within the therapeutic range.

The PK profile is marked by large peaks and valleys, sometimes exceeding the therapeutic level, and sometimes falling below. The PK profile of the LAI formulation is much “smoother,” having no significant peaks and valleys. Also, the oral bioavailability of ibrutinib is only 3% and varies among patients. The LAI formulation, meanwhile, is 100% bioavailable and therefore can be administered at much lower per-day doses.

These factors above could reduce side effects caused by off-target receptor interactions, while maintaining efficacy, and result in fewer cases in which the medication needs to be discontinued. The LAI formulations of two weeks and one month ensure patient adherence for these periods, possibly enhancing efficacy in clinical practice.

Similar benefits may be possible with other immunomodulatory cancer pharmaceuticals, such as the thalidomide analog pomalidomide (Pomalyst), indicated for multiple myeloma. The recommended dose for multiple myeloma is 4 mg per day taken orally on days 1 through 21 of repeated 28-day cycles. The half-life is approximately 7.5 hours and oral bioavailability is estimated to be approximately 75%. The LAI formulation reduces the peaks and valleys of drug exposure, enables a reduction in the total amount of drug administered, reduces the frequency of doses, possibly reduces side effects, and ensures patient adherence.

Additional Benefits to Highlight

Along with administration approaches and the long-term effects on the body, LAIs as oncology pharmaceuticals possess several key advantages for the patient, including:

- Reduced treatment burden

- Increased patient compliance

- Sustained stable hormone suppression

How Oakwood Labs Is Contributing to Cancer Drug Development

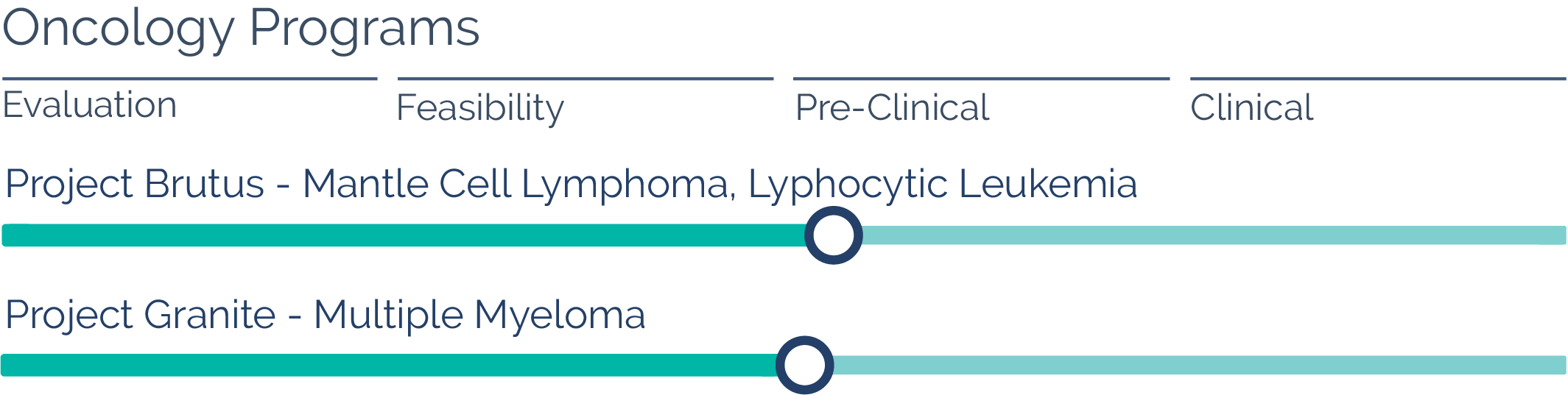

Alongside working with external partners who have been seeking out LAIs for their own initiatives, our team is also currently in the process of creating internal programs that utilize our very own microparticle technology. The goal of these internal initiatives is to convert an existing product into an LAI formulation to extend the duration of drug release to what is currently on the market, achieving patient compliance and ease of use.

More specifically, Oakwood Labs has used its internal technology to progress its formulations that are focused on treating mantle cell lymphoma, small lymphocytic lymphoma, chronic lymphocytic leukemia, and multiple myeloma with release durations ranging anywhere between two and four weeks. Our LAI oncology drug development has led to significant benefits for patients, such as:

- Reducing the amount of drug administered to the patient

- Decreasing the number of doses needing to be injected

- Diminishing more adverse reactions and side effects from dosages

Partnership Opportunities

At this point in the cancer drug development process, our team is actively seeking an external partner to help further develop our internal program. Key responsibilities in this area include funding ongoing development activities as well as phases one through three of clinical trials and registration/commercialization efforts.

If you’re interested in learning more about this opportunity, please contact our team directly, as we would be happy to provide additional details or answer any questions you may have.

FAQs About Oncology Pharmaceuticals, Development, and More

Can you provide me a brief history of oncology pharmaceutical development and its breakthroughs?

Though it is estimated that the preliminary study and treatment of cancer was initially recorded as early as 520 BCE when Persian queen Atossa was treated for a breast tumor, modern-day pharmaceuticals for treating cancer did not surface until relatively recently. Just some of the pivotal findings in this scientific journey include:

- The 1840s – Physician Rudolf Virchow is well-known for his observation of cancer cells during this time, in which he defined their key characteristics. This led to the future of cancer treatment protocols by the start of the 20th

- 1895 – Once German physicist Wilhelm Conrad Röntgen first correctly identified the waves of radiation that we all now know as X-rays, this equipment was then used in radiotherapy cancer treatment shortly thereafter.

- The 1940s – Based on the discovery that nitrogen mustard contains anticancer properties during World War II, researchers were able to develop various cytotoxic drugs to directly target dividing cancer cells, which later led to today’s chemotherapy practices.

Can you tell me more about the work Oakwood Labs does to develop LAIs?

Oakwood Labs performs LAI development through our technology platform Chroniject™, and some characteristics of products we have made with this system including the following:

- The duration of release is one week to one year

- LAIs are easily syringable with 18- to 23-gauge needles

- Products are reconstituted immediately with sterile water

- LAIs are filled aseptically and terminally sterilized if feasible

- Products have proven content uniformity and good stability characteristics

- LAIs are free of foreign particulate matter

Additionally, Chroniject™ is microsphere-based and has biodegradable polymers such as PLA, PLGA, and other polymers with demonstrated low toxicity and sourced from multiple suppliers. Plus, the finished dosage form typically consists of a lyophilized vial containing microspheres, a suspending agent, and other excipients.

What are the current barriers to an LAI entering this particular space?

The barrier to entry is that LAI formulations are extremely difficult to develop and require a high degree of technical expertise. Once developed, you then need to scale up the process to be able to manufacture in an aseptic GMP facility. The Oakwood Labs team can work with you to overcome key challenges.

What are some common trends in the development of drugs to treat cancer?

As healthcare professionals and pharmaceutical developers continue to produce different types of drugs for treating cancer, numerous trends have emerged from their discoveries, such as:

- Targeted drugs for treatment

- Immunotherapy

- Monoclonal antibodies

- Small molecule-targeted agents

- CRISPR

- Biomaterials, such as chitosan oligosaccharide (COS)

These recent practices have significantly advanced the oncology field, leading to longer, happier, and healthier lives for patients undergoing treatment.

Contact Oakwood Labs for More Information

If you have any additional questions about the oncology drug development process, or if you’re looking to get in touch with us regarding a potential partnership opportunity, please contact our team today. We look forward to assisting you.

Different health conditions and disorders can require a range of tactics for successful treatment, and mental and emotional issues patients face are no exception. Conditions such as depression, schizophrenia, bipolar disorder, and more require reliable medications paired with other forms of therapy to elicit the best results, which is where the team at Oakwood Labs comes in.

We’re adept at developing long-acting injectables for treating major depressive disorder and other conditions, and we’ve successfully manufactured and scaled up formulations for diverse clients. Read on to learn about our depression pharmaceutical development and other key services.

A Brief History of Depression Pharmaceutical Development

The age of modern antidepressant drugs began in the early 1950s when researchers who were attempting to cure tuberculosis instead noticed that two of the chemicals found in their test batch compounds – isoniazid and iproniazid – improved the mental states of test subjects.

Research continued until the initial phase of depression pharmaceutical development was under way, leading to tricyclic antidepressants and monoamine oxidase inhibitors. Though a step forward for the greater cause, side effects these drugs produced were troublesome, leading to more research and development being necessary in the field. Despite some of their associated issues, drugs of these type are still prescribed in some cases.

The second phase of research focused on key neurotransmitters and divided medication into the categories of selective serotonin reuptake inhibitors and norepinephrine reuptake inhibitors. SSRIs tended to be much safer than the previous drugs on the market, though they were not always as effective, leading to the development of SNRIs, which covered a larger selection of neurotransmitters.

All of the drugs that fell under these classifications traditionally were administered through the means of oral medication, though that is changing in the modern era. The viability of utilizing injectables for treating depression is becoming more recognized, paving the way for new treatments and advancements.

Our Process for Developing Long-Acting Injectables to Treat Major Depressive Disorder

At Oakwood Labs, when it comes to creating long-acting injectables for depression, schizophrenia, bipolar disorder, and other conditions, we stand out as being one of the few independent companies that can develop these products from concept to FDA approval.

Our facilities utilize proven technology that has shown scalability from 5-10 g starting batch size to 32 kg commercial batch size, and we also have the ability to manufacture our products aseptically within our own GMP facility.

When it comes to injectables for treating depression, Oakwood Labs partners with organizations to work on external projects, and we also have an extensive internal development project pipeline within the CNS space. We are actively looking to partner with organizations, so if you have a project in mind be sure to contact us.

How We Overcome Difficulties

One barrier for using long-acting injectables to treat major depressive disorder is the difficulty in formulating and manufacturing these drugs aseptically. In order to develop and commercialize a product, you need specialized drug delivery technology and an effective process, such as the one used at Oakwood Labs.

Our process allows for a customized release profile for every product, and the ability to scale up that formulation for a commercial batch size.

Benefits of Shifting from Oral Medications to Long-Acting Injectables to Treat Depression

One of the primary advantages to making this change is patient compliance, as patients who suffer from schizophrenia, depression, bipolar disorder and other conditions sometimes do not want to take a prescribed drug, or they forget to. That is why many schizophrenia drugs, for instance, are now available in both oral and long-acting injectable forms.

Other major benefits of using long-acting injectables include:

- Reducing the number of required injections

- Being able to target specific anatomical areas

- Helping to prevent drug abuse

All of these aspects can help contribute to better care, assisting facilities and doctors in providing the best for their patients.

Our Services Beyond Depression Pharmaceutical Development

When you choose to partner with Oakwood Labs, you’ll be working with a global leader in sustained-release drug delivery who can supply a range of services. Some of our offerings beyond injectables for treating depression include:

- Microsphere formulation development

- Formulation optimization and scale-up

- Analytical method development

- GMP aseptic manufacturing

- Contract manufacturing

Please review specifics about each service on their respective pages, and get in touch with us if you are interested in beginning a project.

Contact Oakwood Labs Today

If you’re looking to partner with an experienced team to produce long-acting injectables for major depressive disorder and other conditions, Oakwood Labs is your resource. Get in touch with us and we’ll help you determine a plan of action.

There are many routes of drug delivery, including oral, intravenous, intramuscular, transdermal, inhalation, and subcutaneous. The choice of route will depend on the desired onset of action, the medication’s properties, and patient preferences.

Subcutaneous, or subQ, drugs are delivered below the skin into the layer of tissue beneath the dermis and epidermis. They are typically administered using a needle, which allows the drug to be absorbed into the bloodstream and distributed throughout the body. Read on to learn about key facets of subcutaneous drug delivery and development and how the Oakwood Labs team can assist you with the process.

Understanding the Benefits of Subcutaneous Delivery of Drugs

The subcutaneous delivery of drugs works to balance effectiveness, convenience, and patient comfort while providing therapeutic relief. The location of an injection is usually preferred on the thigh, stomach (around the belly button), or the upper outer arm. The injection device often depends on the dose, ergonomic design for ease of use, and other factors, but can include syringes with attached needles, prefilled syringes, autoinjectors, and pen injectors. Drugs that are administered subcutaneously include insulin for diabetes, growth hormones, anticoagulants, vaccines, and certain types of chemotherapy drugs.

The benefits of subcutaneous drug delivery include:

- Fast absorption – Depending on the drug being administered, it is possible for subcutaneous drugs to absorb rapidly into the bloodstream because they bypass the digestive system. This leads to a quicker onset of action, making them ideal for anything that requires quick effects or emergency treatments.

- User-friendly application – Did you know that some EpiPens use subcutaneous delivery? When not administered through an intramuscular route, EpiPens can use subcutaneous drug delivery in the upper thigh to treat allergic reactions, which means they are able to be used by patients of almost any age.

- Improved bioavailability – Certain drugs have poor oral bioavailability due to degradation in the digestive tract or metabolism in the liver. Subcutaneous delivery of a drug improves its bioavailability because it releases the drug directly into the circulation of the system.

- Reduced variability in absorption – Oral medications can be impacted by food intake and gastrointestinal factors. Subcutaneous drug delivery provides more consistent and reliable absorption, which offers more consistent results.

- Versatility – Subcutaneous delivery is ideal because it is typically less painful and offers a larger range of possible injection sites when compared to intramuscular injections.

- Sustained-release design – There are specific drugs that can be delivered subcutaneously over an extended period of time. This results in more stable drug levels in the bloodstream, which improves patient compliance by removing the need for frequent dosing.

Using Sustained-Release Subcutaneous Drug Delivery

Using sustained-release subcutaneous drugs provides a controlled and prolonged release of medicine into the bloodstream. This results in consistent therapeutic effects for patients and reduces the need for frequent visits. Additionally, it reduces any side effects because the formulations are created to consistently deliver the drug, therefore minimizing peak drug concentrations. When starting the development of sustained-release, subcutaneous-delivery drugs, there are many different factors to consider, including drug solubility, release kinetics, biodegradability, and compatibility with the injection method.

Once it’s time to formulate the subcutaneous drug that uses sustained-release technology, it is essential to consider the matrix systems, microsphere or nanoparticle formulations, and implantable devices. If you need assistance with your subcutaneous drug development, the dedicated team at Oakwood Labs is ready to get to work on your project.

Choose Oakwood Labs for Developing Subcutaneous-Delivery Drugs

Since 1997, Oakwood Labs has been operating a fully compliant, aseptic cGMP manufacturing facility that is designed to manufacture sustained-release injectable pharmaceutical products, and we are adept at subcutaneous drug development.

Our team is committed to creating pharmaceutical products that provide enhanced therapeutic benefits to patients and returns to our pharmaceutical partners, using our Chroniject™, a patented polymer-based injectable microsphere system for drug delivery. Be sure to use our team’s expertise and our cutting-edge facility for your next project.

Contact Us About Subcutaneous Drug Development

For more information on our abilities in subcutaneous drug development, please contact us today. We’re ready to assist you.

Related Blog Posts

Learn about the background of intra-articular injections, the means of treatment, and what it’s like to work with Oakwood Labs to develop them for your operations.

The History of Intra-Articular Injections

Intra-articular injections were the product of a few different methods of pre-existing treatments and have evolved alongside technology and discoveries within the medical space to become what they are today. Part of the origin for intra-articular injections derived from joint aspiration, where healthcare professionals would remove fluid from the joint space and assess the fluid for any inflammatory conditions or infections.

Another milestone that helped in the development of intra-articular injections was the introduction of corticosteroids in injections. These substances have powerful anti-inflammatory properties and were found to be effective in the treatment of joint inflammation. Therefore, it made sense to test them in intra-articular injections, which proved to be a success.

Additionally, advancements in imaging techniques like ultrasounds and fluoroscopy helped increase the accuracy and precision of intra-articular injections, as these tools can help guide the needle during injection.

As ongoing research and innovation occurred, more discoveries about intra-articular injections were made. These advancements continued to encourage the production of the best treatments possible, and clinical guidelines and standardizations ensured proper administration, patient safety, and optimal outcomes.

Today, intra-articular injections are used widely in rheumatology, orthopedics, and sports medicine to provide relief to patients. Typically, these patients have osteoarthritis, rheumatoid arthritis, gout, tendinitis, bursitis, joint effusion, or post-operative swelling.

Medications Utilized in Intra-Articular Injections

Depending on their needs and previous medical history, candidates for intra-articular injections are typically treated with the following:

- Corticosteroids – As mentioned above, corticosteroids like cortisone can be extremely therapeutic for patients who have joint pain. Corticosteroids are very powerful anti-inflammatory medications that alleviate joint pain by reducing swelling and inflammation.

- Hyaluronic acid – Hyaluronic acid is a substance that is naturally found in joint fluid and can be injected to provide lubrication and cushioning in joints. It is often used to treat conditions like osteoarthritis.

- Platelet-rich plasma – PRP is used to promote healing and reduce pain and inflammation in patients. It is derived from the patient’s blood and is rich in both platelets and growth factors.

Let Our Team Help

If you are looking for a partner who can assist with manufacturing intra-articular injections, Oakwood Labs is ready to step in. We use a patented technology called ChronijectTM to help you treat patients through parenteral drug administration, the umbrella term that refers to delivering medications and other therapeutic benefits through routes other than the digestive tract. Intra-articular delivery is one of the ways to do this.

The Oakwood Labs team operates in an FDA-approved, aseptic facility and is committed to adhering to Good Manufacturing Practices to ensure product safety and quality. From material sourcing and formulation to sterilization, filling, packing, and beyond, the Oakwood Labs team is there with you every step of the way in the manufacturing process. We have been manufacturing pharmaceutical treatments since 1997, and look forward to continuing to innovate into the future.

Contact Oakwood Labs for Intra-Articular Injection Manufacturing

If you are ready to provide therapeutic relief to patients with joint pain through intra-articular injection manufacturing, be sure to contact us today.

We look forward to working with you on your next project.

Animal pharmaceuticals are treatments that are designed to prevent, diagnose, or treat disease in animals to promote overall well-being. This goal applies to a variety of animals, including livestock, poultry, and even wildlife.

The world of animal health pharmaceutical development has also played a significant role in the fast-growing and evolving world of pet pharmaceuticals. Read on to learn about all of these aspects and how Oakwood Labs can partner with your facility for effective pharmaceutical development.

Our Process for Animal Health Drug Development

The demand for animal health pharmaceuticals is rising due to population growth, urbanization, changes in dietary habits, increased awareness of animal welfare, and more. To keep up with this demand, the industry continues to shift via research, new technology, and regulations that address the evolving needs of animals.

Discover the advantages of animal health pharmaceutical development:

- Improved animal health and welfare – Veterinary pharmaceuticals are a way to provide effective treatments for infections and chronic conditions. Just like humans, pets and livestock need treatments when they fall ill or have an ongoing condition, and these treatments make symptoms much more tolerable for the animal and its owner.

- Disease prevention and control – Injectables and other preventative medicines help control the spread of infectious diseases among animals, which reduces the risk of outbreak and transmission to other animals and even humans in some cases.

- Companion animal care – Pharmaceuticals for pets address varied health concerns, including pain management, behavioral issues, and chronic diseases. Having medicines that treat these problems gives owners a way to provide optimal care for their pet, fostering stronger bonds.

- Food safety and security – Pharmaceuticals are critical for maintaining the health of livestock and poultry, which leads to safer and higher-quality animal-derived food products. This results in a better food supply chain by reducing the risk of foodborne illnesses.

FAQs About Animal Health Pharmaceutical Development

To help you get a better understanding of animal health pharmaceutical development, we listed some FAQs that might clear up some confusion on the subject.

What is the general process for animal health drug development?

Animal health pharmaceutical development follows a similar process to that of drug manufacturing for humans. The stages include research and discovery, preclinical testing, regulatory approval, clinical trials, manufacturing, quality control, and post-market surveillance. The FDA oversees the approval and safety of animal health pharmaceuticals, ensuring that they meet the standards for efficacy.

What are some recent developments in animal health pharmaceuticals?

Discoveries in the area of animal health pharmaceutical development are being made constantly. Some of the more notable ones made recently include the development of novel drug technologies, the discovery of new treatment modalities, and the use of genomics and biotechnology to develop customized medicine for animals.

How do long-acting injectables benefit animal health drug development?

Long-acting injectables offer sustained therapeutic effects through a single injection, which is convenient for both animals and their caregivers. This method of administration minimizes stress for animals and improves treatment adherence, which leads to better outcomes for a variety of health conditions.

Work with Oakwood Labs for Animal Health Drug Development

At Oakwood Labs, we have a full-service cGMP manufacturing facility that hosts a range of contract manufacturing services. We produce commercial products for use by both humans and animals, and our batch sizes range from 1,000 to 20,000 vials per batch. In our GMP manufacturing facility, we are able to accomplish the following:

- In-house QC microbiology and QC chemistry

- Raw material dispensing and weighing

- Non-aseptic formulation

- Equipment preparation and staging

- Compact and portable equipment train

- Aseptic formulation

- Aseptic filling

- Aseptic lyophilization

- Vial capping

- Inspecting, labeling, and packaging

- Shipping and receiving

In addition to these capabilities, we also bring more than 20 years of experience to your project. We would love to be your partner in animal health drug development.

Contact Us Today About Animal Health Pharmaceutical Drug Development

When you are ready to get started with animal health pharmaceutical drug development, we are ready to assist.

Be sure to contact us today with any questions you might have.

Best known for their versatile role in a vast array of chemical applications, organic solvents play a crucial role in numerous sectors, including the medical industry.

To gain a better understanding of how these solvents can contribute to pharmaceutical practices and manufacturing techniques for drug delivery, review our complete guide for more information.

An Overview of Organic Solvents

As industry experts are aware, organic solvents are solvents that contain carbon atoms capable of either dispersing or dissolving one or more substances. Due to their chemical makeup, these solvents can be utilized in a variety of industries, such as textiles, cleaning, agriculture, and pharmaceuticals.

Additionally, common characteristics and properties of suitable organic solvents include the following:

- High volatility

- Acid-based properties

- Low boiling point

- Suitable density

As opposed to some inorganic solvents, organic solvents can also be described as combustible and extremely flammable. That’s why we advise that those looking to work with organic solvents in long-acting injectables, or processes such as spinning and dyeing textiles, ensure that they are handling these carbon-based solvents with the utmost care.

The Role of Organic Solvents in Long-Acting Injectables

Organic solvents in pharmaceuticals, such as long-lasting injectables, can contribute to an expansive array of roles throughout the drug delivery process, such as the following:

- Dissolving drugs at high concentrations – Organic solvents can be utilized to dissolve drugs, such as biologics, that otherwise have a higher concentration and a lower aqueous solubility. That way, long-acting injectables can be administered at the appropriate viscosity and form drug depots under the skin’s surface.

- Forming drug depots – Drug depots, or depot injections, are longer-duration drugs that result in a slow absorption into the bloodstream. Though organic solvents can contribute to the formation of these drug depots, the administration of the drug into your muscle is best when using a depot.

- Determining the rate of release – Once the drug depot has formed, organic solvents decelerate the rate of their delivery, resulting in a more gradual, sustainable release and absorption of the medication over time.

A Look at Organic Solvents in Pharmaceuticals: Their Industry Uses and Beyond

Along with their inherent contribution to the production of long-lasting injectables, organic solvents in pharmaceuticals play many key roles in the total industry. Beyond mainly being utilized as reaction media, organic solvents are used in the following processes:

- The purification of synthesis products

- Excipients, such as coloring agents, preservatives, and fillers

- The bioavailability of orally administered protein-active sites

- Semiempirical models of meditated solubility

- Antisolvent crystallization techniques in pharmaceutics

Additionally, organic solvents can even be used in water-based cleaning solutions. This is because they are capable of penetrating oily soil deposits while also dissolving in water.

FAQs About Organic Solvents, Their Capabilities, and More

What are the most common organic solvents used in pharmaceutical manufacturing?

The most common applications when working with organic solvents in pharmaceuticals include the following:

- Acetone

- Dimethylformamide

- Diethyl ether

- Benzene

- Isopropanol

- Ethanol

What safety precautions should be taken when working with organic solvents in pharmaceuticals?

As stated previously, organic solvents can be extremely flammable and volatile, so handling them with care is essential. With that in mind, here are some stringent safety regulations you should abide by during the manufacturing process:

- Gloves and safety glasses should be worn when handling the materials

- A fume-hood is required when pouring out organic solvents

- Spill kits and eyewash stations should be readily available in the workspace

- Flammable liquids, such as bleach, peroxides, and acids, should be stored away from organic solvents

Can organic solvents be reused or recycled?

Yes, organic solvents can be recycled easily and reused in syntheses. This includes collected solvents that are separated by distillation and have different boiling points.

Contact Oakwood Labs for More Information

As your trusted resource for sustained-release injectables and other services, Oakwood Labs is well-equipped with the necessary tools to satisfy your application needs.

For more information about organic solvents in pharmaceuticals, long-acting injectables, and more, please reach out to our team today. We look forward to assisting you.