Author Archives: Mark Ilhan

Choosing the most effective method is based on many different factors but include the patient and their medical history, desired outcome, type of drug, and more. Long-acting injectables are one method of drug administration that is particularly favorable among clinical professionals due to the convenience and effectiveness. Below, we’ll review the benefits of different types of long-acting injectables and how they are developed and manufactured.

What Is a Long-Acting Injectable?

A long-acting injectable is an injection method which allows for the gradual release of medication into the bloodstream. There are different types of long-acting injectables, and their effects can last anywhere from two to twelve weeks with just one dose depending on the medication.

Different types of long-acting injectables are commonly used as alternative treatments for those individuals who have trouble taking daily or regular medicines in the form of liquids, tablets, or capsules.

Different Types of Long-Acting Injectables

Since their introduction into clinical practices in the early 1960s, long-acting injectable antipsychotic drugs have been widely used as maintenance therapy and a reliable treatment option for those with psychotic disorders, such as schizophrenia.

These different types of long-acting injectables vary in terms of how often they need to be administered as well as how long their medical benefits will last. A few of the most commonly administered long-acting injectable antipsychotic drugs used today include:

- Fluphenazine

- Haloperidol decanoate

- Risperidone

Answering the Question: Why Are Different Types of Long-Acting Injectables Important?

Long-acting injectable drugs allow for the slow release of medicine into the blood and their effects can last anywhere from two to twelve weeks, making them a practical option for those who have trouble taking medicine on a regular or daily basis. Other benefits of these different types of long-acting injectables include:

- No need to remember to take medications every day

- Routine interactions between patient and medical staff for injection visits

- Overall reduced relapse frequency and rehospitalization rates

- Reduces the risk of accidental or purposeful overdose

- Treating patients with more stable plasma concentrations than oral medications

Considerations When Utilizing Long-Acting Injectables

As with any clinical solution or medication, there are potential side effects to these different types of long-acting injectables that are dependent upon various factors. Some considerations to these drug alternatives may include:

- Prolonged period to achieving steady-state levels

- Slow dose titration

- Less flexibility of dose adjustment

- Delayed desertion of distressing and/or severe side effects

- Pain at the injection site can occur

- Leakage into the subcutaneous tissue and/or the skin can cause irritation

- Burden of frequent travel to outpatient clinics or home visits by community nurses for their administration

- Perception of stigma

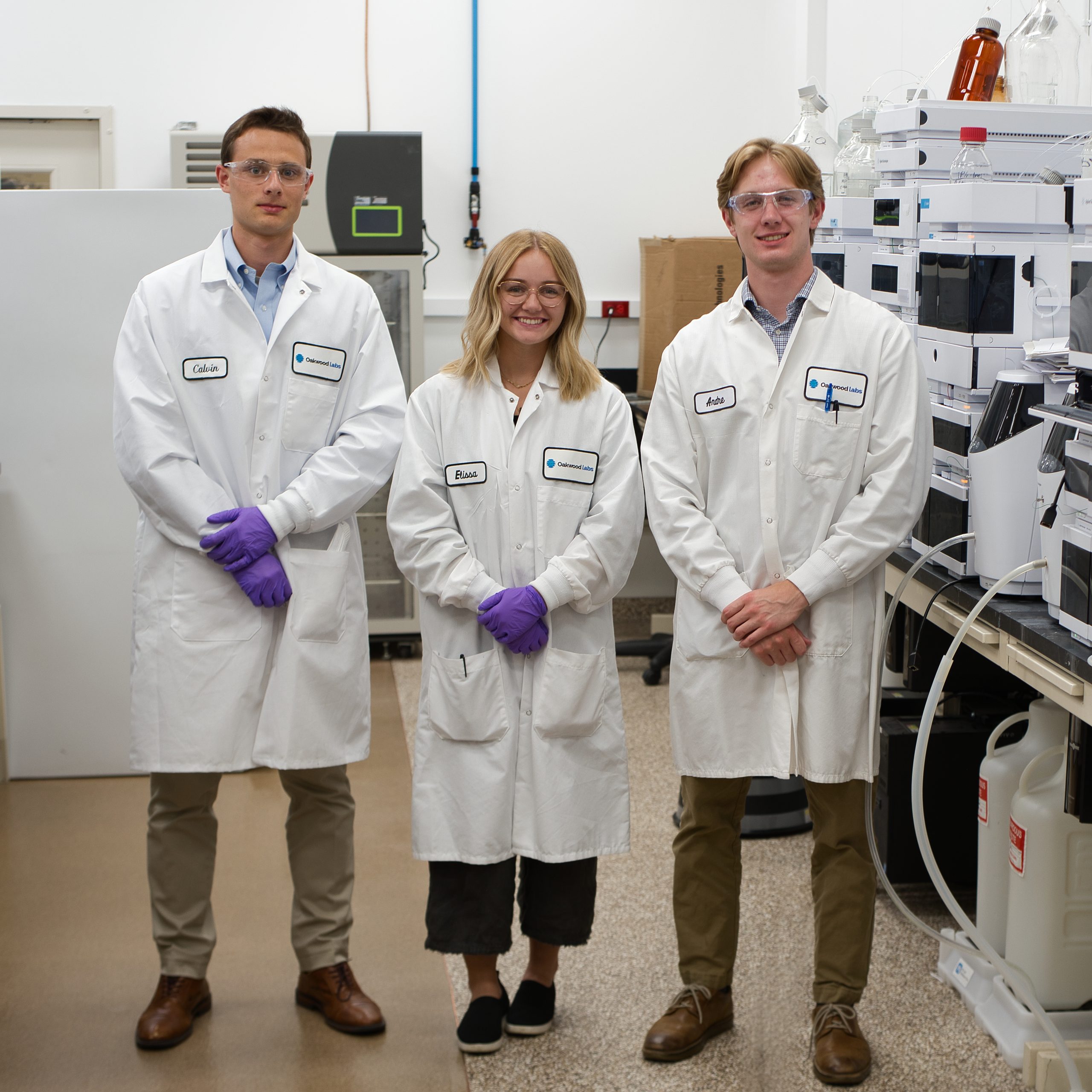

Many Different Types of Long-Acting Injectables Can Be Manufactured at Oakwood Labs

Oakwood Labs is a leading developer of sustained-release pharmaceuticals with over 20 years of drug encapsulation experience. We offer support throughout the development of different types of long-acting injectable, ultimately achieving a product that provides greater remedial benefits to patients around the world.

Our facilities can provide the following to help achieve your project goals, including those involving various types of long-acting injectable:

- Pre-formulation development

- Feasibility studies

- Scaling formulation

- Toxicology batch manufacturing

- ICH compliant stability tests

- Phase I, II, and III clinical trial manufacturing

- GMP manufacturing (commercial and aseptic)

Contact Us Today to Learn More!

Long-acting injectables are a proven method to preventing the intense symptoms associated with mental illnesses and psychotic disorders. Using this clinical method has the ability to put patients on the path to a more stable and prosperous life.

The team at Oakwood Labs is ready to assist in the development and manufacturing of different types of long-acting injectable drugs. Reach out today to get started on your next project with us.

We look forward to working with you!

The first step is conducted through two different studies. At Oakwood Labs, we first select a target formulation to receive tests during the feasibility study and then again with the in vivo animal study. After that is complete, it’s then time for the scale-up process to commence.

Understanding what pharmaceutical scale-up is and the importance of the process in the pharmaceutical industry can help businesses increase the number of products that are growing in demand.

Defining the Scale-Up Process

The scale-up process is designed to increase the amount of an existing product, taking production from a smaller scale to a larger scale during a short duration of time.

Our pharmaceutical scale-up process involves increasing the development of the formulation while still making the same product attributes as we normally would. Through the scale-up process in pharmaceuticals, we offer our clients quality assurance and validations to any concerns they may have.

Important Factors to Consider for the Scale-Up Process in the Pharmaceutical Industry

When tested drugs are ready for the pharmaceutical scale-up process, there are important factors to consider. To make sure your product is in an ideal position for market success, there is a need for focused and careful planning. Also, when drugs are first going through the pharmaceutical scale-up process they are continuously being optimized. Within our continuous flow process, the equipment we use to manufacture prototype formulations is the same that is used to manufacture full-scale lots, facilitating an easy transition and ensuring the process goes smoothly.

Familiarizing Yourself with the Different Scale Stages

There are different stages of the pharmaceutical scale-up process that drugs undergo. When a drug is in the first stages of receiving tests, it is at the laboratory-scale level. Pilot scale follows and is designed for the purpose of expanding clinical trials. Production scale for commercial use is the final scale in the cycle and is implemented when a new drug is approved. At Oakwood Labs, we can guide your product through the needed scales, providing consistency and reproducibility that lead to the best results.

Contact Us Regarding Our Scale-Up Process in Pharmaceuticals

If you’re in need of scale-up for your pharmaceutical products, be sure to reach out. We are an industry leader in sustained-release injectable pharmaceutical development and manufacturing, and we are committed to supplying products that provide enhanced therapeutic benefits to patients.

Contact us to learn more about the pharmaceutical scale-up process or our other manufacturing capabilities.

When caring for patients, it is critical to use medical treatments that are not only effective but also seamlessly incorporate into their lifestyles. With the risks associated with pills and the need for a regular routine, medical personnel often will turn to long-acting injectable antipsychotics for patient treatment due to the approach’s benefits.

Long-acting injectable antipsychotic drugs are commonly used for patients who experience unpleasant adverse side effects of antipsychotic drugs and are hesitant to believe they have a mental illness. While this form of medicine does not require the daily administration that other antipsychotics do, they are able produce relief to patients in need.

Administering Long-Acting Injectable Antipsychotics

Long-acting injectable antipsychotics can be utilized with diverse medications, making them ideal for patients suffering from an assortment of issues. Along with this, long-acting injectable antipsychotics are often administered in two-, three- or four-week intervals, but treatments can vary based on the patient’s needs. Time between injections also differs based upon the administered drug and its ability to stay within the system.

Candidates for this treatment often include patients with a history of non-adherence, severe symptoms, comorbid substance abuse, and cognitive impairment. Additionally, this method is extremely beneficial to patients who experience ambivalence or negative attitudes toward medications.

Why Long-Acting Injectable Antipsychotics Are Ideal for Patients

There are many advantages to using long-acting injectable antipsychotics on eligible individuals, as they can improve the lives and routines of patients in the following ways:

- Reduced accountability – In order for medications to work best, it is important for patients to take them every day according to instructions. Since long-acting injectable antipsychotics stay in the system for extended periods of time, they reduce the need for a daily reminder to take the drug.

- Regularity – By using long-acting injectable antipsychotics, the need for medical appointments increases. This creates regular interactions between the patient and medical staff, creating a more comfortable environment, providing more social interactions, and solidifying a routine.

- Stability – The long-acting injectable method treats patients with more stable plasma concentrations than oral medications. It also lessens the frequency of having peak plasma levels, which can result in fewer side effects for the patient. Lastly, it reduces relapse frequency and rehospitalization rates, making it a great alternative for those who are prone to hospital visits already.

- Safety – Since long-acting injectable antipsychotic drugs are administered by medical personnel, they are safer for patients. The approach reduces the risk of accidental or deliberate overdose through the use of regulated injections that work gradually over time.

Oakwood Labs Is Ready to Help You Produce Long-Acting Injectable Antipsychotics and More

Oakwood Labs is a leading manufacturer of sustained-release pharmaceuticals with over 20 years of drug encapsulation experience. We offer support throughout the phases of long-acting injectable development, ultimately achieving a product that provides enhanced therapeutic benefits to patients everywhere.

In our facilities, we can provide the following to help achieve your project goals, including those involving long-acting injectable antipsychotics:

- Pre-formulation development

- Feasibility studies

- Scaling formulation

- Toxicology batch manufacturing

- ICH compliant stability tests

- Phase I, II, and III clinical trial manufacturing

- GMP manufacturing (commercial and aseptic)

Contact Us Today to Learn More!

Long-acting injectable antipsychotics are a way to steadily prevent the intense symptoms associated with mental illnesses. Using this approach has the ability to put patients on the path to a stable and successful life.

The team at Oakwood Labs is ready to help with the development of your long-acting injectable antipsychotic drugs. Please reach out today and get started on your project with us!

Clinical trials are defined as research studies that involve people.

A Phase 3 clinical trial is the stage at which a new drug is tested for efficacy and adverse reactions on a group of volunteers ranging in size from 300 to 3,000.

The Phases of a Clinical Trial

- Phase 1 – Testing the safety and dosage of a new drug, the first phase of a clinical trial is conducted on a pool of 20 to 100 volunteers over the course of several months. Approximately 70% of drugs move on to Phase 2.

- Phase 2 – Conducted over the course of a few months up to a few years, Phase 2 of a clinical trial is meant to test the efficacy and side effects of a new drug on a group ranging from 100 to several hundred people.

- Phase 3 – Phase 3 clinical trials are conducted on 300 to 3,000 volunteers over the course of one to four years. This stage continues to test for the efficacy of a new drug while monitoring for adverse reactions.

- Phase 4 – In the final phase, several thousand volunteers undergo clinical trials to further test for the safety and efficacy of the medicine.

Phase 3 Clinical Trial – Efficacy and Monitoring Adverse Reactions

With a length of one to four years, a Phase 3 clinical trial is more likely to show researchers long-term or rare side effects to a medication. This is the phase in which most of the safety data about the new drug is gathered, as it’s possible that less-common side effects have failed to be detected in earlier, shorter phases of the clinical trial up to this point.

Phase 3 clinical trials are designed by researchers to show whether or not a product is a beneficial treatment to a specific population of people. Only 25-30% of drugs move on to Phase 4.

Designing a Phase 3 Clinical Trial

At Oakwood Labs, we have extensive experience in producing global clinical trial material for Phase 1, 2, and 3 clinical trials. Through our Microbiology and Chemistry groups, we offer full characterization capabilities – proper documentation of batch release and accelerated and long-term stability studies.

As our team makes progress in development, the process will be validated. Multiple lots of API and polymer are used in the Phase 3 clinical trial process to demonstrate the product. We recommend conducting Phase 3 clinical trials on the same scale as intended for commercial scale to avoid delays in commercialization if clinical trials are successful.

Key Elements of a Phase 3 Clinical Trial

Regulatory agencies rely on the data derived from Phase 3 clinical trials, so it’s essential that these trials meet rigorous standards. Some key elements that make up a Phase 3 clinical trial include:

- Large sample size – You can expect a Phase 3 clinical trial to involve a large group of participants, such as hundreds to thousands of people, in order to provide statistically meaningful results and show differences between treatments.

- Multi-site execution – These trials are conducted across various locations such as in hospitals or clinics, but also could be conducted internationally. This ensures that findings can be applied to diverse populations.

- Blinding protocols – Ideally, these trials should be double-blind, meaning that neither the clinician nor patient knows which treatment is being given. This ensures there is no bias involved in procedures and that the process is fully randomized.

- Safety monitoring – All Phase 3 trials require monitoring by a data and safety monitoring board (DSMB) since these trials are large and conducted at various sites.

How Long Does a Phase 3 Clinical Trial Last?

There is no requirement when it comes to a timeline for Phase 3 clinical trials, but they are often longer and require a follow-up. You can expect the trial to last 1–4 years. The extended length is due to the comprehensive tests conducted during this phase to evaluate the drug’s long-term effects.

Ensure Quality in All Phases of Clinical Trials with Oakwood Labs

Our team utilizes a continuous flow process in the scale-up process of your drug – we run the process longer and control the downstream processing so that the product is not changed over the course of the run. Additionally, we validate the scale-up process prior to the manufacture of clinical trial materials, and we use Quality by Design (QbD) principles and develop specific Design of Experiments (DoE) to increase the scale-up success.

From scale-up to Phases 1, 2, and 3, our team has the right combination of knowledge and expertise to guide you through the process of a clinical trial.

Contact Us for Your Phase 3 Clinical Trials

We are proud to be your source for all phases of long-acting injectable (LAI) development. With over two decades of drug encapsulation experience, our team is here to work with you on your proof of concept, feasibility studies, clinical trial material, and FDA-approved commercial supply.

In need of guidance for your Phase 3 clinical trial? Contact our team today!

The goal of clinical trials is to identify whether a designated treatment will benefit an identified population. This process applies to brand-new treatments that develop as well as treatments that were developed with the intention of replacing an older, less effective one.

From start to finish, the process of developing medicine is conducted methodically. Once your formulation has been scaled up and is ready to be tested on the intended human population, it is time to move on in the process to Phase 1 and Phase 2 clinical trials.

Phase 1 Clinical Trials

During a Phase 1 clinical trial, the goal is ultimately to evaluate the safety of a drug. It is often started with a smaller sample of healthy individuals who volunteer to be tested on. This gives insight into how the drug will impact the overall population and sparks research questions for Phase 2 clinical trials.

The Process

In the process of Phase 1 clinical trials, the group is first injected with a small dose of the medicine and monitored. Often, researchers are looking for severe side effects, since this is the first time the drug is being tested on the intended population. It is also common to look for the amount of a drug that is in the blood after administration and the overall effects of the drug on the body.

Researchers may also look for the side effects associated with increasing the dosage of the drug. This is helpful in determining the maximum dosage of the drug that can be administered without side effects. After notes are taken, they are evaluated and researched before moving onto Phase 2 of a clinical trial.

Phase 2 Clinical Trials

In a Phase 2 clinical trial, the goal is to perfect the dosage and test its effectiveness. Ultimately, this equates to the idea of maximizing benefits while minimizing risks to the user. In this step, the medicine is rigorously tested for its success in treating, preventing, or diagnosing a problem or disease.

The Process

During Phase 2 clinical trials, it is typical to test a much larger sample to better understand the drug’s effectiveness. Phase 2 can be thought of as comprising two halves. The first half focuses on dosing, where patients are given different amounts of the drug. It is important to carefully monitor changes when administering different doses. The second half of the trial is reserved for testing the efficacy of the drug.

After these steps are completed, the drug is then evaluated for its benefits and risks. Should the benefits outweigh the risks of the drug, the testing moves on to Phase 3 clinical trials for further assessment.

Choose Oakwood Labs as Your Clinical Trial Destination

Your Phase 1 and 2 clinical trials are critical to providing the public with effective medicine. The testing that needs to be conducted to make sure drugs are safe and effective for patients is extensive. When you discover a new drug that you want to take to market, it is important to be supported by a team that is both knowledgeable and experienced.

Oakwood Labs has the environment and qualified team needed to assist in the development of your treatment. Since 1997, our team has been providing therapeutic benefits to patients through the use of sustained-release pharmaceutical injectables. We operate in a fully FDA-compliant aseptic manufacturing facility to enhance our development capabilities and range of services.

Additionally, we have the ability to help with other projects. We offer the following services, making us the source for supporting all phases of long-acting injectable development:

- Feasibility studies

- Analytical development

- Scale-up capabilities

- GMP clinical trial material

- GMP contract manufacturing

Choose Oakwood Labs as Your Clinical Trial Destination

Oakwood Labs is equipped with the supplies, team, and facilities to help you plan and execute Phase 1 and 2 clinical trials. Contact us today to get started on your next project.

Our expertise and long history of industry compliance and experience has allowed us to grow and remain a reliable provider of pharmaceutical contract manufacturing services. We recognize the importance of GMP protocols within our aseptic facility and are proud to operate an internationally recognized GMP aseptic processing facility.

GMP Overview

Good Manufacturing Practice, or GMP, is a system used worldwide to ensure products are produced and controlled in accordance with industry quality standards. This is especially important in the pharmaceutical industry.

The sensitive nature of medicines, medical-grade equipment, and medical products can present risks if these items are not produced and handled in a safe and controlled manner. When it comes to pharmaceutical products, anything less than high-quality GMP production could pose health hazards – especially if a lack of quality control leads to an unsafe product. Lax oversight can also result in financial repercussions.

Additionally, GMP is important to help increase business and export opportunities. GMP is internationally recognized as the standard for quality production, which is why many countries will only accept the import and sale of pharmaceutical products that have been manufactured under a GMP system.

Key Features of Our GMP Aseptic Processing Facility

At Oakwood Labs, we take a strategic approach to maintaining an FDA-approved manufacturing aseptic facility. Using an ISO classification system for controlled areas, Oakwood Labs operates and maintains a full suite of core and support manufacturing operations. Some of the key features include:

- In-house QC Microbiology and QC Chemistry

- Raw material dispensing and weighing

- Non-aseptic formulation

- Equipment preparation and staging

- Compact and portable equipment train

- Aseptic formulation

- Aseptic filling

- Aseptic lyophilization

- Vial capping

- Inspecting, labeling, and packaging

- Shipping, receiving, and warehouse space

Services Offered at the Oakwood Labs Aseptic Facility

With our GMP aseptic facility and our expertise in pharmaceutical manufacturing, we are able to provide a variety of services at Oakwood Labs. Some of the services we offer include:

- Formulation and analytical development activities

- Accelerated and long-term stability studies

- Scale-up, validation, and engineering batches

- Clinical and commercial scale batch production

- Complete method transfers and validation

- Batch record and protocol development

Analytical method development and validation can be a complex, costly, and a labor-intensive process. However, at Oakwood Labs, we supply a full range of analytical capabilities in-house in our R&D labs and in our aseptic GMP manufacturing facility, which is FDA approved and meets GMP standards.

By offering these services in-house, our analytical and formulation teams can work closely together and provide quick turnaround on results, assisting in formulation development. Plus, both our R&D facility and GMP aseptic facility have fully functioning labs to support release testing of final products.

Additionally, communication and project management are important parts of our process. Prioritizing these aspects ensures that we are able to achieve the milestones we strive for in a timely and cost-effective manner. Furthermore, our team of highly skilled scientists have years of experience working with diverse products, methods, and technologies.

Learn More About Our GMP Aseptic Facility

Located just outside of Cleveland, Ohio, Oakwood Labs is a specialty pharmaceutical research and development company focused on producing and manufacturing sustained-release injectable pharmaceuticals.

We have partnered with and provided services for many businesses across varied industries. For two decades, our advanced technology, manufacturing capabilities, and internationally recognized GMP aseptic facility have enabled us to grow and supply the highest-quality pharmaceutical services and products.

Contact Us Today

Contact the team at Oakwood Labs today to learn more about the services we offer and how we maintain a GMP aseptic processing facility. We are looking forward to working with you.

With over 20 years of experience developing time-release pharmaceuticals, Oakwood Labs is a trusted industry source for pharmaceutical products that include PLA and PLGA microspheres. PLGA and PLA polymers are FDA-approved biodegradable and biocompatible polymers that have been used in medical devices, including microspheres.

PLA Microspheres vs. PLGA Microspheres

PLA and PLGA microspheres are widely studied polymers in the medical field, as they allow for the encapsulation of the desired active pharmaceutical ingredient or drug. The PLA microspheres aide in controlling the release of the drug from the polymer matrix and allow for a sustained release of the drug over a period of time that can vary from weeks to several months.

PLA microspheres exhibit asymmetric centers in their backbone which result in either D or L forms, producing PDLA or PLLA. PLGA is the copolymer of D, L-lactic acid with glycolic acid.

While both PLA and PLGA microspheres are insoluble in water, their absorption of water causes them to degrade over time. The methyl groups of PLA microspheres decrease the water uptake properties of the polymer, thereby extending its time-release properties.

One of the most important factors that affects the degradation rate of PLA and PLGA microspheres is the molecular weight of the polymer. Crystalline parts of the polymer exhibit more resistance to degradation. As Keles states, “the crystallinity of the polymer depends on compositions. For example, increasing the percentage of glycolide monomer in PLGA backbones decrease polymer crystallinity.”

PLA and PLGA Microspheres Play a Critical Role

One advantage of working with PLGA and PLA microspheres is the fact that the polymers can be used to encapsulate almost all types of drugs. This includes:

- Small molecules

- Peptides

- Polypeptides

- Proteins

It’s possible for the microspheres to have such diverse abilities because they come in a variety of comonomer ratios, molecular weights, and end-capping configurations. This allows the release duration to be tailored for each specific drug. In addition, the release profile, such as the burst release, can be modified by choosing the appropriate polymer for the reaction.

The release profile of the drug over time is dependent on the specific drug that is being encapsulated by the PLA and PLGA microspheres. Interactions between the polymers and the drug can be positive or adverse and require an in-depth understanding to develop a successful microsphere product.

Our Process of Developing PLGA and PLA Microspheres

In initial production stages, we utilize small batches to allow for testing of a multitude of trial batches and rapid production. As we develop the formulation with the desired time-release profile and additional desired characteristics, we then refine methods of production. Our processing of developing PLA and PLGA microspheres starts in small batches to ensure that all desired properties are met and can then be scaled to a commercial production process.

Our Chroniject™ PLA/PLGA microsphere time-release injections are a leader in the industry and have several key benefits. Some of the benefits include:

- Rapid development of formulations with small-scale batches that are easily scalable

- Proven lot-to-lot reproducibility

- Flexible release durations that vary from one week to one year

- Applications in multiple therapeutic indications (CNS, neurology, ophthalmology)

Contact Us for Your PLA/PLGA Microsphere Needs

Oakwood Labs is equipped to support all development phases of time-release drugs using our PLA/PLGA microsphere technology. If you are interested in knowing more about how our microspheres can help you, contact our team today.

Oakwood Labs was founded over 20 years ago as a specialty pharmaceutical company, and we operate as a one-stop source for all aspects of long-acting injectable development. Our focus is placed on developing and manufacturing sustained-release injectables that function to benefit the intended population.

When looking at pharmaceutical development, it is important to take a systematic approach for all of the necessary steps. While we are equipped to assist in any stage of the process, it is important to work patiently in sequential order. For a new project, a pharmaceutical feasibility study is the first step in the process.

Defining a Pharmaceutical Feasibility Study

When you first set out to release a new drug product into the market, it is important to have goals and objectives in mind, and pharmaceutical feasibility studies help assess the practicality of a proposed idea. Put simply, this process is the study of total actions and outcomes.

Pharmaceutical feasibility studies determine processing factors that will lead to an optimized outcome for your pharmaceutical project, which gives confidence that the goals of the process can be achieved. It also can uncover aspects of a project that are capable of fully changing the scope, analyzing these aspects to avoid wasting resources in the future.

The Importance of Conducting Pharmaceutical Feasibility Studies

Feasibility studies are an essential step in the development process because they help determine the suitability of a particular project. The overall purpose looks to determine whether your process is designed properly and precedes the scale-up and development of the sustained-release formulations.

A pharmaceutical feasibility study can also be used to better understand risks that you might encounter and challenge critical manufacturing components. With this progression, you will better understand the expectations against the reality of your project, further being exposed to the difference in planned scale, materials, or even equipment.

Achieving Optimal Timing

The timing of this process must be chosen strategically. If all the feasibility steps are not completed, it is possible that you will end up wasting time and resources in the future. The timeline varies based on each individual project, but choosing the right team to work with can mitigate the lifecycle of the project.

Process Breakdown

The overall goal of a pharmaceutical feasibility study is to determine whether a target product profile is achievable. We study this through a multistep process:

- Pre-formulation activities – This involves developing a strategy for batch production. It is possible to select initial polymer and solvent candidates and understand analytical methods that will provide support to the testing process.

- Characterizing feasibility formulations – Our team focuses on producing batches at a small scale when manufacturing. The data from the first iteration of batches is used to determine the next iteration of batches. Characterization results include drug load, particle size, residual solvents, in vitro release profiles, polymer molecular weight and more.

- Finalizing feasibility report – In this step, we compose a report and prepare for the process of outsourced animal testing. We take the lead candidate formulations and prepare materials that can assist in the animal pharmacokinetic (PK) testing process.

Benefits of Working with Oakwood Labs for a Pharmaceutical Feasibility Study

While pharmaceutical feasibility studies can be seen as an in-depth process, we work to make it as simple as possible. With over 20 years of drug encapsulation experience, Oakwood Labs is considered a leader in the pharmaceutical industry. Our research and development labs are filled with state-of-the-art technology, all of which is available to solve pharmaceutical challenges.

Oakwood Labs is the destination for your project, regardless of your current stage. For rapid formulation development, we typically initiate projects with small batches. Every project is carried out with an experienced formulation and analytical team.

If you are looking for additional support during the development of your project, we have other services to help, including:

Request More Information from Oakwood Labs

From pharmaceutical feasibility studies to Phase 3 clinical batches, Oakwood Labs is ready to assist your project.

Request more information today to see how we can help with your next pharmaceutical feasibility study!

This year’s PDA Annual Meeting is occurring April 4-6 in Dallas, TX. This event is focused on the theme of “Level Up: Agility in the New Normal” and will highlight items to look forward to in the future of pharmaceutical manufacturing.

Incorporating speakers, networking events, and panel discussions, this is an event that you will not want to miss. This year, we are excited to announce that we will be featured as an exhibitor.

We Look Forward to Seeing You

Our team has been focused on researching and developing sustained-release injectables, and we are always looking for opportunities to chat about our discoveries and processes. If you are looking for an aseptic lab staffed by experts, consider Oakwood Labs for your next project, as we can assist you in the following:

- Pre-formulation development activities

- Feasibility studies

- Scale-up of formulation

- Manufacturing toxicology batches

- ICH compliant stability testing

- Clinical trial manufacturing (Phase I, II, III)

- Commercial aseptic GMP manufacturing

We are so excited to meet you and show you what we have been working on, so be sure to come to visit the Oakwood Labs team at Booth #308.

Don’t Hesitate to Reach Out

The 2022 PDA Annual Meeting is sure to inform us about new trends and inspire us to be innovative as we take on the pharmaceutical challenges that lie ahead. If you are unable to attend the event, we would be happy to chat about our experience at the occasion or provide information on extended-release technology and more.

Reach out today with any questions you may have. We look forward to seeing you soon!

At Oakwood Labs, we are known for our experience in pharmaceutical research and development. As a premier resource for all phases of development including Phase 1 clinical trials, we continue to lead the industry, delivering products that provide enhanced therapeutic benefits.

A Phase 1 clinical trial is extremely important as it introduces a new drug to human subjects. Considering this study is critical in early phases of drug development, appropriate guidance and guidelines must be in place. To facilitate these Phase 1 clinical trials, Oakwood Labs maintains an aseptic, FDA-approved GMP manufacturing facility.

By having a GMP facility, it allows our team to follow stringent manufacturing practices, ensuring that pharmaceutical products are controlled and produced to the highest quality standards.

The Goal of Phase 1 Clinical Trials

Phase 1 clinical trials place extreme importance on pharma and biotech companies considering that this is how the safety and efficacy of a new drug is tested. Trials are used to assess and outline the best dosing that should be used in later phases, with the Phase 1 clinical trial being a defining moment, as it shows the chances of future commercialization of the drug.

When it comes to Phase 1 clinical trials, some goals include:

- Demonstrating that patients tolerate the drug well under investigation

- Ensuring that any adverse effects seen from these studies will be used to characterize the profile of a new medicinal product

- Determining the correct dosage and testing different schemes of the compound

- Observing preliminary signs of drug efficacy in regards to the condition or disease being treated

Critical Considerations in a Phase 1 Clinical Trial

With the goal of ensuring high-quality research, certain aspects need to be taken into account when designing trials. Some of the key considerations that our team reflects on in Phase 1 clinical trials include:

- Inclusion/exclusion criteria – These entail the characteristics of the subjects being treated in a Phase 1 clinical trial.

- Treatment scheme – This pertains to how the study’s drugs are being administered, suggesting the experimental drug administration dose and sequence with the best chances of success.

- MTD – An approach is required to determine the maximum tolerated dose (MTD) of the experimental treatment. This necessitates defining dose-limiting toxicities (DLTs), and is a central part of a Phase 1 clinical trial.

Oakwood Labs Offers More Than Phase 1 Clinical Trials

Oakwood Labs has over 20 years of experience, providing services for a variety of businesses across different industries. Our manufacturing abilities and advanced technology has allowed us to supply high-quality services and products.

As an industry leader in pharmaceutical development and manufacturing, we are proud to offer numerous services, including:

Contact Oakwood Labs to Learn More About Phase 1 Clinical Trials

Oakwood Labs is committed to developing reliable pharmaceutical products for our pharmaceutical partners, and we provide the expertise and dedicated staff to help you along the way.

Contact our team to learn more about Phase 1 clinical trials and the other services we can provide. We look forward to hearing from you.