Archives by Year: 2024

Opioid abuse disorder is very common, affecting over 20 million people worldwide and over 3 million people in the United States. People who misuse opioids may also advance to even more harmful drugs such as heroin, making this a critical issue that needs to be addressed. With the help of long-acting injectables for opioid use disorder pharmaceutical development, new treatment options are now available to patients that are more sustainable.

The History of Opioid Use Pharmaceuticals

The first modern opioid crisis began in the 19th century. During and after the Civil War, this opioid crisis emerged as soldiers were given substances to treat their wounds, pain, PTSD, and depression. As a result, many soldiers developed an opioid addiction. Doctors at this time would give a patient morphine because it was a general cure for all chronic pain problems, but it obviously had negative effects as well.

The opioid crisis dwindled by 1900, and for roughly 90 years opioids were only abused by smaller groups of people. It wasn’t until the early 2000s that the use of opioids once again began affecting communities all over the country. While doctors started to notice the spread of opioids and took steps to curtail it, people were finding other ways to illegally acquire the drugs.

While there are still issues today, we have grown more aware of the risks that are associated with opioid use. There are many efforts being made to hopefully reduce instances of abuse, such as educating those on alternate pain management strategies, developing abuse-deterrent formulations, having stricter prescription guidelines in place, and offering opioid use disorder pharmaceutical development.

Benefits of Long-Acting Injectables for Treating Opioid Use Disorder

Long-acting injectable, or LAI, formulations ensure that patients receive their medications on a regimented schedule. Drugs such as naltrexone and buprenorphine are formulated as monthly injections in order to block the effects of opioids. Initially, these drugs were formulated in daily oral dosages, but LAI products are more effective, as they result in greater patient compliance.

In addition to improved compliance, injectables to treat opioid abuse disorder provide benefits such as:

- Ability to target specific anatomical areas – LAI buprenorphine targets the receptors in the brain, providing effects that help control withdrawal symptoms, reduce cravings, block the euphoric effects of opioids, and maintain stable blood concentrations without peaks.

- Helping to prevent drug abuse – By receiving long-acting injections, patients eliminate the need for daily dosing, reducing the risk of missed doses and relapses.

- Potential for improved outcomes – Injectables help reduce the opportunities for misuse and ensure consistent medication levels are maintained, possibly leading to better outcomes for the patient.

How Oakwood Labs Stands Out

Oakwood Labs has developed 2-, 3-, and 4-month duration prototype formulations of naltrexone, using a different polymer than is used in the 1-month duration naltrexone. We are currently working on scaling up these formulations prior to clinical trials.

We also have a track record of success in bringing other projects from proof of concept to clinical trials, such as proving the duration of release of naltrexone formulations in animal PK models. We are currently seeking partners for clinical development.

By choosing us as a partner in developing injectables to treat opioid use disorder, you’ll benefit from:

- Strong communication and project management that achieves milestones

- Patented microsphere technology that allows tailored release profiles from weeks to one year

- Over 20 years of experience encapsulating sustained-release injectables

- A full-service operation, from R&D formulation development through GMP commercial manufacturing

- An FDA-approved aseptic GMP facility manufacturing clinical and commercial sterile injectables

FAQs on Injectables to Treat Opioid Use Disorder

How do these medications work?

Naltrexone helps block the sedative and euphoric effects of drugs such as codeine, morphine, and heroin. This medication is reported to reduce opioid cravings. Buprenorphine, on the other hand, helps avoid withdrawal symptoms and manage cravings.

What are the current barriers to an LAI entering this particular space?

It is difficult to develop LAI formulations of these drugs, especially for formulations in excess of one month in duration of release. Currently, 1-month duration products have been approved, but no longer than 1-month duration products have been approved yet. Some people are working to develop longer duration products, such as a 2-month duration naltrexone and a 3-month duration buprenorphine. It is generally accepted that longer duration products would be beneficial for patient compliance.

Who are good candidates for injectables?

People who may benefit from injectables for treating opioid use disorder and other conditions include:

- Those who are high-risk, meaning they experience frequent hospitalizations or multiple relapses

- Those who prefer less frequent dosing

- Those who are nonadherent to oral antipsychotics

- Those experiencing dose-dependent adverse effects

- Those who have poor oral absorption

Besides opioid use disorder, what else can LAIs help treat?

Long-acting injectables have been used to treat a variety of conditions such as schizophrenia, bipolar disorder, depression, and more. LAIs have also been used as pharmaceuticals which offer numerous benefits for oncology treatment.

Choose Oakwood Labs for Opioid Abuse Disorder Pharmaceutical Development

If you have an interest in long-acting injectables for treating opioid use disorder, please reach out to us today. We look forward to providing you with more information on how to tackle this ongoing issue in today’s world.

Oakwood Labs will be exhibiting at Booth #31 and speaking at the upcoming 2024 PODD Conference taking place from October 28-29 in Boston. If you would like to learn more about the event and register to attend, please visit the following link: https://poddconference.com/

Company Overview

Oakwood Labs is a global leader in sustained release drug delivery. We support all phases of long acting injectable development from initial feasibility studies through FDA-approved clinical and commercial supply. Oakwood has 27 years of drug encapsulation experience using Chroniject™, our patented microsphere-based technology. Chroniject™ provides the ability to control particle size, customize release durations from weeks to years, and minimize residual solvents to achieve critical quality attributes.

Listen to Oakwood’s presentation during Day 1 on our Chroniject Technology: A Solution to Long Acting Injectable Formulation and Scale-Up Challenges

Colin Spencer, a project manager working within our technology transfer team will be presenting during Day 1 (Monday, October 28th) of the conference within the Track 1A: Injectable Formulations & Technologies at 2:30pm.

The presentation will include the following key points:

- Oakwood’s Chroniject technology provides a tunable long-acting injectable platform for a wide array of molecules and applications. Efficacious release profiles have been generated from as fast as two days to as long as one year.

- Oakwood’s Chroniject technology provides the platform for scale-up of the formulation process, allowing for the critical quality attributes of the long-acting injectable formulations to be maintained from initial feasibility batch sizes in the gram-scale to clinical and commercial batch sizes in the kilogram-scale.

Stop by Oakwood Lab’s Booth #31 to meet our team and learn more about how we can assist in the following areas:

- Long Acting Injectable Patented Technology (CDMO Services)

- Feasibility assessments

- Scale-up and optimization of lead formulation

- Manufacturing, characterization, and stability of R&D toxicology batches

- GMP Clinical trial manufacturing (Phase I, II, III)

- GMP Commercial manufacturing

- Contract Manufacturing (CMO Services)

- Technology Transfer

- GMP Registration and Validation batches

- Aseptic GMP commercial batch manufacturing

- ICH compliant stability testing

Contact Us for More Information

PODD 2024 conference covers a wide range of topics, and we are happy to contribute to the event! If you aren’t able to attend, but still want to learn more about Oakwood Labs or what you missed at the conference, contact us today!

We look forward to discussing our technology and more.

Oakwood Labs is happy to announce that we will be exhibiting at Booth #2610 at the upcoming 2024 AAPS PharmSci 360 on October 20-23 in Salt Lake City, Utah. If you would like to learn more about the event and register to attend, please visit the following link: https://www.aaps.org/pharmsci/annual-meeting

Company Overview

Oakwood Labs is a global leader in sustained release drug delivery. We support all phases of long acting injectable development from initial feasibility studies through FDA-approved clinical and commercial supply. Oakwood has 27 years of drug encapsulation experience using Chroniject™, our patented microsphere-based technology. Chroniject™ provides the ability to control particle size, customize release durations from weeks to years, and minimize residual solvents to achieve critical quality attributes.

Stop by Oakwood Lab’s Booth #2610 to meet our team and learn more about how we can assist in the following areas:

- Long Acting Injectable Technology (CDMO)

- Feasibility studies

- Scale-up of formulation

- Manufacturing toxicology batches

- Clinical trial manufacturing (Phase I, II, III)

- Contract Manufacturing (CMO)

- Technology Transfer

- GMP Registration and Validation batches

- Aseptic GMP commercial batch manufacturing

- ICH compliant stability testing

Contact Us for More Information

The AAPS 2024 conference covers a wide range of topics, and we are happy to contribute to the event! If you aren’t able to attend, but still want to learn more about Oakwood Labs or what you missed at the conference, contact us today!

We look forward to discussing our technology and more.

Joint pain affects many people around the world, creating problems with everyday tasks, causing discomfort, and lessening their quality of life. Fortunately, advances in medicine have led to relief for those who suffer from a variety of conditions that result in joint pain, with long-acting injectables being an efficient method of delivery.

At Oakwood Labs, we’re a leader long-acting injectable development, putting our proven methodologies to work in drugs to treat joint pain. Read on to learn more about joint pain drug development and how the Oakwood Labs team can supply exactly what your operations need.

The History and Use of Long-Acting Injectables for Joint Pain Pharmaceuticals

Long-acting injectables were created in the 1950s to aid patients suffering from mental health conditions such as schizophrenia. As procedures evolved and new developments arose in the ensuing decades, the treatment of other conditions, including those centered more on the total body rather than just the mind, began to emerge. This includes using long-acting injectables to administer drugs for treating joint pain in knees, elbows, shoulders, and other problem areas.

Some of the common conditions that are suited for long-acting injectable medication distribution include:

- Osteoarthritis

- Rheumatoid arthritis

- Bursitis

- Tendonitis

- Psoriatic arthritis

Meanwhile, there are a range of medication types that may be distributed. These can include osteoarthritis pharmaceuticals, rheumatoid arthritis pharmaceuticals, and other forms, with specific injections containing:

- Corticosteroids

- Hyaluronic acid

- Platelet-rich plasma

- Additional formulations

Key Benefits of Long-Acting Pharmaceutical Drugs to Treat Joint Pain

Long-acting injectables, sometimes referred to as extended-release drugs or “ER drugs,” help to provide ongoing pain relief to patients who are suffering from an array of conditions. The result is a better quality of life, better pain management, increased mobility, and fewer dosages. Other benefits of these pharmaceuticals for treating joint pain include:

- Fewer side effects – Using long-acting injectable pharmaceuticals to treat joint pain can result in fewer side effects for patients because they will receive less frequent dosages than with immediate-release approaches. The reduced side effects are also facilitated by patients receiving lower peak concentrations of the given drug.

- Improved patient compliance – Since long-acting joint pain pharmaceuticals necessitate fewer doses, patients who take them are more likely to follow the plan put in place by their healthcare professionals. This results in improved pain management and happier patients.

- Reduced pain level fluctuations – Patients who take immediate-release drugs may notice a fluctuation in pain levels for their joint issues, but long-acting injectables lessen this experience, offering a more stable and controlled release that manages pain.

Our Abilities in Joint Pain Drug Development

The Oakwood Labs team has been proud to tackle projects for osteoarthritis drug development and rheumatoid arthritis drug development, providing long-acting injectables with a release duration of three months.

Our team specializes in developing pharmaceuticals that treat joint pain and can assist with developing formulations, scaling up the manufacturing process, and manufacturing clinical and commercial quantities under GMPs.

We find that long-acting injectables are ideal for use with pharmaceuticals for treating joint pain because joint pain often emanates from a specific bodily area and high concentrations of a drug can be administered without resulting in systemic exposure. This, and the potential for disease-modifying results, are yet more benefits to the LAI approach.

Our Work with LAI Formulations

In terms of our work, Oakwood has developed a 3-month LAI formulation of meloxicam. Meloxicam is one of the more potent NSAIDs, which enables targeted release in the intra-articular space, and thus avoids the systemic side effects of NSAIDs. Due to the high potency of meloxicam, a smaller injection volume is possible.

Challenges We Have Faced

One of the current barriers to entering this particular space is the difficulty of developing the proper formulation. Microspheres are preferable to gels that solidify after injection due to the mechanics of the joint and intra-articular space. Microspheres should be greater than 20 microns to avoid macrophages attacking them. Work with our team of LAI experts to develop the right formulation.

Partner with Us on Drugs to Treat Joint Pain

Oakwood Labs is actively looking to partner with interested organizations for co-development of programs such as those focused on treating joint pain. Be sure to visit our partnership page for more information on our approach and all areas we focus on. We would love to work with you to bring new drugs to market.

Have Questions About Pharmaceuticals to Treat Joint Pain? Contact Us

Reach out to the team at Oakwood Labs today and we can discuss our methodologies, facilities, previous projects, and more. We look forward to hearing from you.

At Oakwood Labs, we’re proud to contribute to the development of cancer pharmaceuticals through our continuous work manufacturing long-acting injectables (LAIs). That’s why we’ve compiled an informational guide showcasing our ongoing work in the healthcare field, as well as the numerous benefits of LAIs for oncology treatment.

Advantages of Long-Acting Injectables to Treat Cancer

There are numerous advantages to the use of LAIs as pharmaceuticals to treat cancer. To start, Bruton tyrosine kinase (BTK) inhibitors are established standards of care in multiple B-cell malignancies including chronic lymphocytic leukemia, mantle cell lymphoma, and Waldenstrom macroglobulinemia. LAI formulations of BTK inhibitors offer certain advantages in terms of pharmacokinetics (PK) and patient adherence. For example, ibrutinib (Imbruvica) has a very short half-life of 4-6 hours. Hence, relatively large doses of the oral form are required to target plasma levels within the therapeutic range.

The PK profile is marked by large peaks and valleys, sometimes exceeding the therapeutic level, and sometimes falling below. The PK profile of the LAI formulation is much “smoother,” having no significant peaks and valleys. Also, the oral bioavailability of ibrutinib is only 3% and varies among patients. The LAI formulation, meanwhile, is 100% bioavailable and therefore can be administered at much lower per-day doses.

These factors above could reduce side effects caused by off-target receptor interactions, while maintaining efficacy, and result in fewer cases in which the medication needs to be discontinued. The LAI formulations of two weeks and one month ensure patient adherence for these periods, possibly enhancing efficacy in clinical practice.

Similar benefits may be possible with other immunomodulatory cancer pharmaceuticals, such as the thalidomide analog pomalidomide (Pomalyst), indicated for multiple myeloma. The recommended dose for multiple myeloma is 4 mg per day taken orally on days 1 through 21 of repeated 28-day cycles. The half-life is approximately 7.5 hours and oral bioavailability is estimated to be approximately 75%. The LAI formulation reduces the peaks and valleys of drug exposure, enables a reduction in the total amount of drug administered, reduces the frequency of doses, possibly reduces side effects, and ensures patient adherence.

Additional Benefits to Highlight

Along with administration approaches and the long-term effects on the body, LAIs as oncology pharmaceuticals possess several key advantages for the patient, including:

- Reduced treatment burden

- Increased patient compliance

- Sustained stable hormone suppression

How Oakwood Labs Is Contributing to Cancer Drug Development

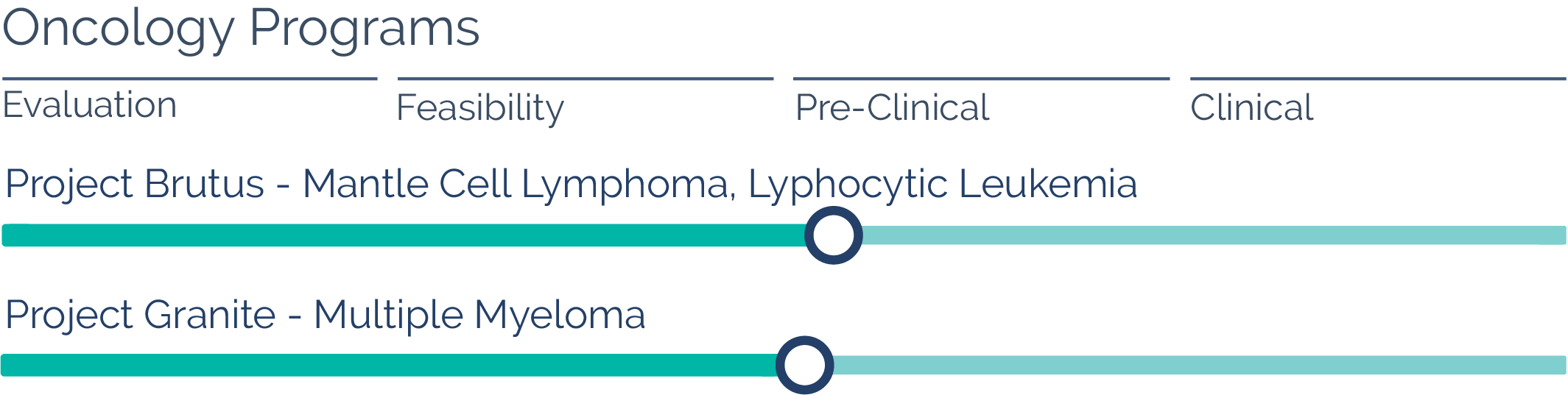

Alongside working with external partners who have been seeking out LAIs for their own initiatives, our team is also currently in the process of creating internal programs that utilize our very own microparticle technology. The goal of these internal initiatives is to convert an existing product into an LAI formulation to extend the duration of drug release to what is currently on the market, achieving patient compliance and ease of use.

More specifically, Oakwood Labs has used its internal technology to progress its formulations that are focused on treating mantle cell lymphoma, small lymphocytic lymphoma, chronic lymphocytic leukemia, and multiple myeloma with release durations ranging anywhere between two and four weeks. Our LAI oncology drug development has led to significant benefits for patients, such as:

- Reducing the amount of drug administered to the patient

- Decreasing the number of doses needing to be injected

- Diminishing more adverse reactions and side effects from dosages

Partnership Opportunities

At this point in the cancer drug development process, our team is actively seeking an external partner to help further develop our internal program. Key responsibilities in this area include funding ongoing development activities as well as phases one through three of clinical trials and registration/commercialization efforts.

If you’re interested in learning more about this opportunity, please contact our team directly, as we would be happy to provide additional details or answer any questions you may have.

FAQs About Oncology Pharmaceuticals, Development, and More

Can you provide me a brief history of oncology pharmaceutical development and its breakthroughs?

Though it is estimated that the preliminary study and treatment of cancer was initially recorded as early as 520 BCE when Persian queen Atossa was treated for a breast tumor, modern-day pharmaceuticals for treating cancer did not surface until relatively recently. Just some of the pivotal findings in this scientific journey include:

- The 1840s – Physician Rudolf Virchow is well-known for his observation of cancer cells during this time, in which he defined their key characteristics. This led to the future of cancer treatment protocols by the start of the 20th

- 1895 – Once German physicist Wilhelm Conrad Röntgen first correctly identified the waves of radiation that we all now know as X-rays, this equipment was then used in radiotherapy cancer treatment shortly thereafter.

- The 1940s – Based on the discovery that nitrogen mustard contains anticancer properties during World War II, researchers were able to develop various cytotoxic drugs to directly target dividing cancer cells, which later led to today’s chemotherapy practices.

Can you tell me more about the work Oakwood Labs does to develop LAIs?

Oakwood Labs performs LAI development through our technology platform Chroniject™, and some characteristics of products we have made with this system including the following:

- The duration of release is one week to one year

- LAIs are easily syringable with 18- to 23-gauge needles

- Products are reconstituted immediately with sterile water

- LAIs are filled aseptically and terminally sterilized if feasible

- Products have proven content uniformity and good stability characteristics

- LAIs are free of foreign particulate matter

Additionally, Chroniject™ is microsphere-based and has biodegradable polymers such as PLA, PLGA, and other polymers with demonstrated low toxicity and sourced from multiple suppliers. Plus, the finished dosage form typically consists of a lyophilized vial containing microspheres, a suspending agent, and other excipients.

What are the current barriers to an LAI entering this particular space?

The barrier to entry is that LAI formulations are extremely difficult to develop and require a high degree of technical expertise. Once developed, you then need to scale up the process to be able to manufacture in an aseptic GMP facility. The Oakwood Labs team can work with you to overcome key challenges.

What are some common trends in the development of drugs to treat cancer?

As healthcare professionals and pharmaceutical developers continue to produce different types of drugs for treating cancer, numerous trends have emerged from their discoveries, such as:

- Targeted drugs for treatment

- Immunotherapy

- Monoclonal antibodies

- Small molecule-targeted agents

- CRISPR

- Biomaterials, such as chitosan oligosaccharide (COS)

These recent practices have significantly advanced the oncology field, leading to longer, happier, and healthier lives for patients undergoing treatment.

Contact Oakwood Labs for More Information

If you have any additional questions about the oncology drug development process, or if you’re looking to get in touch with us regarding a potential partnership opportunity, please contact our team today. We look forward to assisting you.

Oakwood Labs is happy to announce that we will be at the 2024 Drug Delivery and Formulation Summit on September 17-18 in San Diego. If you would like to learn more about the event and register to attend, please visit the following link: https://ddfsummit.com/DDF2024/en/page/home

Company Overview

Oakwood Labs is a global leader in sustained release drug delivery. We support all phases of long acting injectable development from initial feasibility studies through FDA-approved clinical and commercial supply. Oakwood has 25 years of drug encapsulation experience using Chroniject™, our patented microsphere-based technology. Chroniject™ provides the ability to control particle size, customize release durations from weeks to years, and minimize residual solvents to achieve critical quality attributes.

Stop by Oakwood Lab’s Booth #20 to meet our team and learn more about how we can assist in the following areas:

- Long Acting Injectable Technology

- Feasibility studies

- Scale-up of formulation

- Manufacturing toxicology batches

- Clinical trial manufacturing (Phase I, II, III)

- Contract Manufacturing

- Technology Transfer

- GMP Registration and Validation batches

- Aseptic GMP commercial batch manufacturing

- ICH compliant stability testing

Contact Us for More Information

The DDF 2024 conference covers a wide range of topics, and we are happy to contribute to the event! If you aren’t able to attend, but still want to learn more about Oakwood Labs or what you missed at the conference, contact us today!

We look forward to discussing our technology and more.

Different health conditions and disorders can require a range of tactics for successful treatment, and mental and emotional issues patients face are no exception. Conditions such as depression, schizophrenia, bipolar disorder, and more require reliable medications paired with other forms of therapy to elicit the best results, which is where the team at Oakwood Labs comes in.

We’re adept at developing long-acting injectables for treating major depressive disorder and other conditions, and we’ve successfully manufactured and scaled up formulations for diverse clients. Read on to learn about our depression pharmaceutical development and other key services.

A Brief History of Depression Pharmaceutical Development

The age of modern antidepressant drugs began in the early 1950s when researchers who were attempting to cure tuberculosis instead noticed that two of the chemicals found in their test batch compounds – isoniazid and iproniazid – improved the mental states of test subjects.

Research continued until the initial phase of depression pharmaceutical development was under way, leading to tricyclic antidepressants and monoamine oxidase inhibitors. Though a step forward for the greater cause, side effects these drugs produced were troublesome, leading to more research and development being necessary in the field. Despite some of their associated issues, drugs of these type are still prescribed in some cases.

The second phase of research focused on key neurotransmitters and divided medication into the categories of selective serotonin reuptake inhibitors and norepinephrine reuptake inhibitors. SSRIs tended to be much safer than the previous drugs on the market, though they were not always as effective, leading to the development of SNRIs, which covered a larger selection of neurotransmitters.

All of the drugs that fell under these classifications traditionally were administered through the means of oral medication, though that is changing in the modern era. The viability of utilizing injectables for treating depression is becoming more recognized, paving the way for new treatments and advancements.

Our Process for Developing Long-Acting Injectables to Treat Major Depressive Disorder

At Oakwood Labs, when it comes to creating long-acting injectables for depression, schizophrenia, bipolar disorder, and other conditions, we stand out as being one of the few independent companies that can develop these products from concept to FDA approval.

Our facilities utilize proven technology that has shown scalability from 5-10 g starting batch size to 32 kg commercial batch size, and we also have the ability to manufacture our products aseptically within our own GMP facility.

When it comes to injectables for treating depression, Oakwood Labs partners with organizations to work on external projects, and we also have an extensive internal development project pipeline within the CNS space. We are actively looking to partner with organizations, so if you have a project in mind be sure to contact us.

How We Overcome Difficulties

One barrier for using long-acting injectables to treat major depressive disorder is the difficulty in formulating and manufacturing these drugs aseptically. In order to develop and commercialize a product, you need specialized drug delivery technology and an effective process, such as the one used at Oakwood Labs.

Our process allows for a customized release profile for every product, and the ability to scale up that formulation for a commercial batch size.

Benefits of Shifting from Oral Medications to Long-Acting Injectables to Treat Depression

One of the primary advantages to making this change is patient compliance, as patients who suffer from schizophrenia, depression, bipolar disorder and other conditions sometimes do not want to take a prescribed drug, or they forget to. That is why many schizophrenia drugs, for instance, are now available in both oral and long-acting injectable forms.

Other major benefits of using long-acting injectables include:

- Reducing the number of required injections

- Being able to target specific anatomical areas

- Helping to prevent drug abuse

All of these aspects can help contribute to better care, assisting facilities and doctors in providing the best for their patients.

Our Services Beyond Depression Pharmaceutical Development

When you choose to partner with Oakwood Labs, you’ll be working with a global leader in sustained-release drug delivery who can supply a range of services. Some of our offerings beyond injectables for treating depression include:

- Microsphere formulation development

- Formulation optimization and scale-up

- Analytical method development

- GMP aseptic manufacturing

- Contract manufacturing

Please review specifics about each service on their respective pages, and get in touch with us if you are interested in beginning a project.

Contact Oakwood Labs Today

If you’re looking to partner with an experienced team to produce long-acting injectables for major depressive disorder and other conditions, Oakwood Labs is your resource. Get in touch with us and we’ll help you determine a plan of action.

When developing and manufacturing a new drug, the list of requirements can get extensive. With the needs for drug discovery, development research, review, and production, there are a lot of moving parts to ensure that a product is safe for patients once it hits the market.

Due to this, assistance for the different phases of pharmaceutical drug development is often sought out, and these support companies come in the form of CDMOs, CROs, and CMOs, organizations that serve the pharmaceutical and biotechnology industries. Learn more about the differences between these organizations in our post so you can determine which will be the most beneficial during your pharmaceutical development process.

CRO vs. CMO vs. CDMO

Let’s explore the distinctions between the three types of organizations that can aid you in your pharmaceutical processes.

Contract Research Organization

A Contract Research Organization, or a CRO, is a destination for research, including clinical trial management, preclinical research, data management, regulatory affairs, and post-marketing surveillance. These organizations focus mostly on research and development services, including clinical trials and regulatory compliance. This means they are involved mostly in the early stages of drug development and play a major role in the overall research and regulatory aspects of drug development.

CROs largely support pharmaceutical companies in research and regulations. Outsourcing to a CRO allows the pharmaceutical company to focus on building other areas of the business and prioritizing other tasks.

Contract Manufacturing Organization

A Contract Manufacturing Organization, or a CMO, specializes in the production of pharmaceuticals and all things related to manufacturing. CMOs are adept at handling large-scale production once the drug has been developed. Their services are beneficial because they utilize cutting-edge technology and have skilled employees who bring expertise to the development process.

Working with a CMO also ensures that the final product is compliant with both quality and regulatory standards, which allows the pharmaceutical company to focus on other things like drug discovery and marketing.

Contract Development Manufacturing Organization

A Contract Development and Manufacturing Organization, or a CDMO, offers a full range of services, from drug development through manufacturing. With operations in place for process development, scale-up, clinical trials, material production, and manufacturing, a CDMO is your end-to-end partner.

Because they are involved throughout the ensure lifecycle of drug development and manufacturing, CDMO facilities help pharmaceutical companies to reduce costs, accelerate time to market, and ensure regulatory standards are adhered to. Consult a CDMO to bridge the gap between development and manufacturing and achieve the most comprehensive solution.

Which Partner Is Best for You?

When deciding which organization to work with, be sure to analyze your company’s needs and challenges. If you are seeking a partner for clinical research support, a CRO is your answer. When you need manufacturing help, a CMO is going to be an ideal match. And if you want to outsource the entire process and ensure everything goes smoothly, a full-service CDMO is going to provide comprehensive and integrated development, support, and manufacturing. When you are looking for a reliable CMO or CDMO partner, Oakwood Labs is here to help.

At Oakwood Labs, we offer CDMO and CMO services for your convenience, and our team has over 25 years of experience with developing and manufacturing injectables for the pharmaceutical industry. We specialize in sustained-release and targeted-release injectables for long-term therapeutic relief. Along with this, our facility follows GMP aseptic manufacturing processes to provide FDA-approved pharmaceuticals to our clients.

Learn More About Our Abilities as Your Pharmaceutical Partner

Please contact us today to learn more about everything we can provide as your CMO or CDMO partner. We look forward to assisting you.

There are many routes of drug delivery, including oral, intravenous, intramuscular, transdermal, inhalation, and subcutaneous. The choice of route will depend on the desired onset of action, the medication’s properties, and patient preferences.

Subcutaneous, or subQ, drugs are delivered below the skin into the layer of tissue beneath the dermis and epidermis. They are typically administered using a needle, which allows the drug to be absorbed into the bloodstream and distributed throughout the body. Read on to learn about key facets of subcutaneous drug delivery and development and how the Oakwood Labs team can assist you with the process.

Understanding the Benefits of Subcutaneous Delivery of Drugs

The subcutaneous delivery of drugs works to balance effectiveness, convenience, and patient comfort while providing therapeutic relief. The location of an injection is usually preferred on the thigh, stomach (around the belly button), or the upper outer arm. The injection device often depends on the dose, ergonomic design for ease of use, and other factors, but can include syringes with attached needles, prefilled syringes, autoinjectors, and pen injectors. Drugs that are administered subcutaneously include insulin for diabetes, growth hormones, anticoagulants, vaccines, and certain types of chemotherapy drugs.

The benefits of subcutaneous drug delivery include:

- Fast absorption – Depending on the drug being administered, it is possible for subcutaneous drugs to absorb rapidly into the bloodstream because they bypass the digestive system. This leads to a quicker onset of action, making them ideal for anything that requires quick effects or emergency treatments.

- User-friendly application – Did you know that some EpiPens use subcutaneous delivery? When not administered through an intramuscular route, EpiPens can use subcutaneous drug delivery in the upper thigh to treat allergic reactions, which means they are able to be used by patients of almost any age.

- Improved bioavailability – Certain drugs have poor oral bioavailability due to degradation in the digestive tract or metabolism in the liver. Subcutaneous delivery of a drug improves its bioavailability because it releases the drug directly into the circulation of the system.

- Reduced variability in absorption – Oral medications can be impacted by food intake and gastrointestinal factors. Subcutaneous drug delivery provides more consistent and reliable absorption, which offers more consistent results.

- Versatility – Subcutaneous delivery is ideal because it is typically less painful and offers a larger range of possible injection sites when compared to intramuscular injections.

- Sustained-release design – There are specific drugs that can be delivered subcutaneously over an extended period of time. This results in more stable drug levels in the bloodstream, which improves patient compliance by removing the need for frequent dosing.

Using Sustained-Release Subcutaneous Drug Delivery

Using sustained-release subcutaneous drugs provides a controlled and prolonged release of medicine into the bloodstream. This results in consistent therapeutic effects for patients and reduces the need for frequent visits. Additionally, it reduces any side effects because the formulations are created to consistently deliver the drug, therefore minimizing peak drug concentrations. When starting the development of sustained-release, subcutaneous-delivery drugs, there are many different factors to consider, including drug solubility, release kinetics, biodegradability, and compatibility with the injection method.

Once it’s time to formulate the subcutaneous drug that uses sustained-release technology, it is essential to consider the matrix systems, microsphere or nanoparticle formulations, and implantable devices. If you need assistance with your subcutaneous drug development, the dedicated team at Oakwood Labs is ready to get to work on your project.

Choose Oakwood Labs for Developing Subcutaneous-Delivery Drugs

Since 1997, Oakwood Labs has been operating a fully compliant, aseptic cGMP manufacturing facility that is designed to manufacture sustained-release injectable pharmaceutical products, and we are adept at subcutaneous drug development.

Our team is committed to creating pharmaceutical products that provide enhanced therapeutic benefits to patients and returns to our pharmaceutical partners, using our Chroniject™, a patented polymer-based injectable microsphere system for drug delivery. Be sure to use our team’s expertise and our cutting-edge facility for your next project.

Contact Us About Subcutaneous Drug Development

For more information on our abilities in subcutaneous drug development, please contact us today. We’re ready to assist you.

Related Blog Posts

Learn about the background of intra-articular injections, the means of treatment, and what it’s like to work with Oakwood Labs to develop them for your operations.

The History of Intra-Articular Injections

Intra-articular injections were the product of a few different methods of pre-existing treatments and have evolved alongside technology and discoveries within the medical space to become what they are today. Part of the origin for intra-articular injections derived from joint aspiration, where healthcare professionals would remove fluid from the joint space and assess the fluid for any inflammatory conditions or infections.

Another milestone that helped in the development of intra-articular injections was the introduction of corticosteroids in injections. These substances have powerful anti-inflammatory properties and were found to be effective in the treatment of joint inflammation. Therefore, it made sense to test them in intra-articular injections, which proved to be a success.

Additionally, advancements in imaging techniques like ultrasounds and fluoroscopy helped increase the accuracy and precision of intra-articular injections, as these tools can help guide the needle during injection.

As ongoing research and innovation occurred, more discoveries about intra-articular injections were made. These advancements continued to encourage the production of the best treatments possible, and clinical guidelines and standardizations ensured proper administration, patient safety, and optimal outcomes.

Today, intra-articular injections are used widely in rheumatology, orthopedics, and sports medicine to provide relief to patients. Typically, these patients have osteoarthritis, rheumatoid arthritis, gout, tendinitis, bursitis, joint effusion, or post-operative swelling.

Medications Utilized in Intra-Articular Injections

Depending on their needs and previous medical history, candidates for intra-articular injections are typically treated with the following:

- Corticosteroids – As mentioned above, corticosteroids like cortisone can be extremely therapeutic for patients who have joint pain. Corticosteroids are very powerful anti-inflammatory medications that alleviate joint pain by reducing swelling and inflammation.

- Hyaluronic acid – Hyaluronic acid is a substance that is naturally found in joint fluid and can be injected to provide lubrication and cushioning in joints. It is often used to treat conditions like osteoarthritis.

- Platelet-rich plasma – PRP is used to promote healing and reduce pain and inflammation in patients. It is derived from the patient’s blood and is rich in both platelets and growth factors.

Let Our Team Help

If you are looking for a partner who can assist with manufacturing intra-articular injections, Oakwood Labs is ready to step in. We use a patented technology called ChronijectTM to help you treat patients through parenteral drug administration, the umbrella term that refers to delivering medications and other therapeutic benefits through routes other than the digestive tract. Intra-articular delivery is one of the ways to do this.

The Oakwood Labs team operates in an FDA-approved, aseptic facility and is committed to adhering to Good Manufacturing Practices to ensure product safety and quality. From material sourcing and formulation to sterilization, filling, packing, and beyond, the Oakwood Labs team is there with you every step of the way in the manufacturing process. We have been manufacturing pharmaceutical treatments since 1997, and look forward to continuing to innovate into the future.

Contact Oakwood Labs for Intra-Articular Injection Manufacturing

If you are ready to provide therapeutic relief to patients with joint pain through intra-articular injection manufacturing, be sure to contact us today.

We look forward to working with you on your next project.