Archives by Day: September 15, 2022

The utilization of biodegradable polymers has come a long way during the past few decades. As science and engineering continue to evolve, so do the advancements with utilizing biodegradable polymers in drug delivery. Let’s examine some key aspects.

Starting with the Basics: What Are Biodegradable Polymers?

A biodegradable polymer is engineered to deteriorate over time. These specific polymers have a high molecular weight that depreciates to a lower molecular weight after its intended function. Essentially, once these polymers have served their purpose with appropriate response from the host, they are broken down and eliminated from the body.

Biodegradable polymers are produced both naturally and synthetically. The two most common natural biodegradable polymers include proteins and polysaccharides. Synthetic biodegradable polymers consist of amides, ethers, urethanes, and other esters.

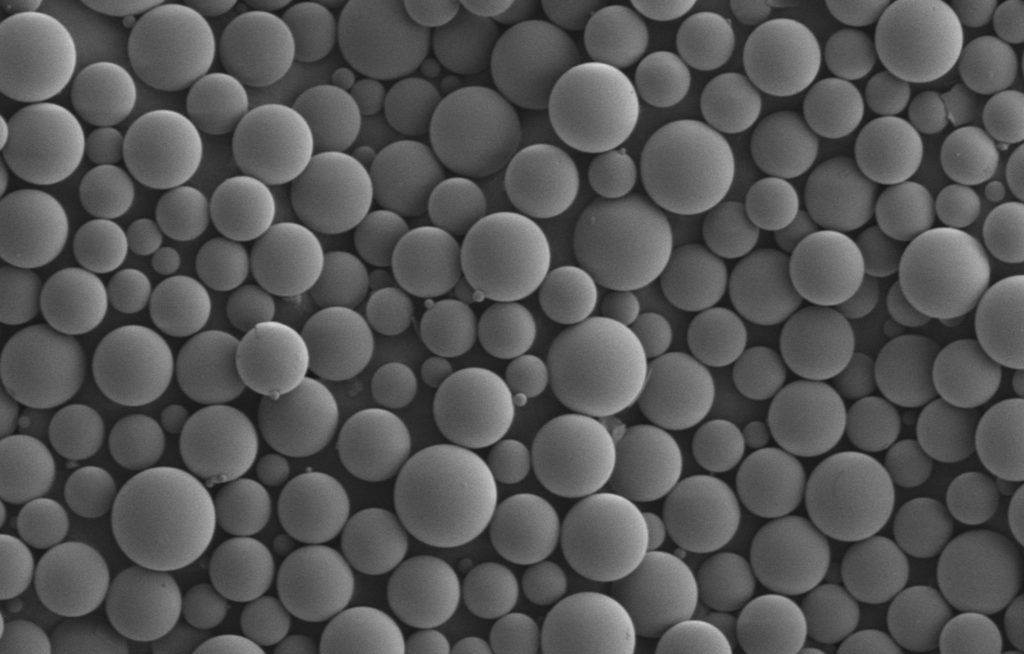

PLA and PLGA are two common biocompatible and biodegradable polymers. These FDA-approved polymers have been used in medical devices, such as microspheres. One of the major benefits of working with biodegradable polymers, such as PLA and PLGA, is that they can be used to encapsulate just about any type of drug, including:

- Proteins

- Peptides

- Polypeptides

- Small molecules

In addition to using biodegradable polymers in controlled drug delivery, they can also be used for the following applications:

- Gene delivery

- Wound dressings

- Tissue regeneration and engineering

- Cryopreservation

- Enzyme immobilization

- Nanotechnology

- Orthopedic fixation devices

- Prosthetics

- Biomedical devices and implants

- Cosmetics

- Augmentation

- Stitches

Why Are Biodegradable Polymers Effective?

Whether biodegradable polymers are natural or synthetic, they have unique biocompatible properties that allow them to decompose inside the body by natural, nontoxic byproducts such as carbon dioxide or water. One benefit to synthetic biodegradable polymers is that they can be produced with a wide range of mechanical, physical, and chemical properties that can be modified. Because these specific polymers can be synthesized by reproducing the same polymer, they have endless availability.

Naturally occurring biodegradable polymers are just as effective as synthetic in that they offer temporary support and aid in controlled release factors throughout the body. Some other major advantages of using biodegradable polymers in drug delivery include:

- Ability to adjust the degradation rates and mechanical properties to form into various configurations

- Decreased need for successive surgical removal, which overall saves money and time

- Sterilizable properties that can be easily processed by the host

- Modifiable surfaces

Biodegradable Polymers at Oakwood Labs

Oakwood Labs is a leader in the pharmaceutical industry providing manufacturing services and contract development. Our state-of-the-art technology allows us to be experts with biodegradable polymers in drug delivery.

At Oakwood labs, we utilize biodegradable polymers such as PLGA, PLA, and other polymers that demonstrate low toxicity. These biodegradable polymers are used in our long acting injectables, which are based upon our technology platform Chroniject™. Our patented microsphere technology is a polymer-based injectable microsphere system for drug delivery.

Other advantages of our technology used for biodegradable polymers in drug delivery include:

- Sourced from multiple suppliers

- Quick and effective development of formulations using small scale batches

- Easily scalable formulations

- Controlled process parameters

- Proven lot-to-lot reproducibility

- Molecule compatibility (peptides, proteins, and small molecules)

- Adjustable release durations ranging from one week to one year

- Exceptional stability

- Immediate reconstitution with WFI with no special diluent needed

- Versatile use in multiple therapeutic applications (neurology, depression, CNS, ophthalmology)

Contact Us Regarding Our Biodegradable Polymers in Drug Delivery

At Oakwood Labs, we have over 20 years of experience with drug encapsulation, which has propelled us to being a leader in sustained release drug delivery. When it comes to using biodegradable polymers in drug delivery, our advanced technology provides the ability to customize release duration ranging from weeks to years.

If you’re interested in learning more about biodegradable polymers, reach out to our team today.

When pharmaceutical companies set out to create new drugs or modify existing ones for innovative applications, the process is necessarily complex, intricate, and thorough. Since any medication goes beyond its status as a product and affects the health and wellbeing of patients, ensuring that these drugs are held to rigorous quality standards and are produced within facilities adhering to the same is essential.

At Oakwood Labs, our dedicated team supplies support for all phases of long-acting injectable development, facilitating a systematic technology transfer process that ensures our clients’ products are delivered safely and securely.

About Technology Transfer for Pharmaceuticals

Technology transfer refers to the process of new inventions and innovations being transformed into products ready for commercialization. While much of the work for these inventions and innovations can occur within lab settings, the results are often intellectual property owned by and created on behalf of corporations or start-ups.

Because of this, the technology transfer process for pharmaceuticals and other focuses seeks to protect the intellectual property of these institutions so that their products can be properly commercialized and monetized, while benefitting medical facilities and patients at large.

Other aspects that can be components of technology transfer for pharmaceuticals include the following:

- Working alongside legal departments securing patents and other rights

- Determining commercial viability of innovations

- Advertising technologies to varied parties

- Teaching principles of and strategizing for commercialization

- Obtaining funding for research

- Planning licensure agreements

- Strategizing business plans for product implementation

As you can see, technology transfer encompasses a wide array of aspects and Oakwood Labs is proud to play a vital role in ensuring that products are crafted to institutions’ specifications and expectations. This helps to guarantee that innovative medicines can advance to further stages and be brought to market, bringing varied advantages to both companies and patients.

Beyond the Technology Transfer Process: Everything That Oakwood Labs Can Provide

When you partner with Oakwood Labs, you gain access to a team with over 20 years of drug encapsulation experience who has provided services for global pharmaceutical firms of diverse sizes. Our expertise in sustained-release drug delivery allows us to provide the reliable, injectable microsphere-based formulations that our clients require.

We are able to supply a host of services and benefits for our clients, such as:

- Chroniject™, our patented microsphere-based technology

- R&D formulation development

- Efficient and stringent process controls

- Tailored release profile from weeks to one year

- GMP manufacturing under rigorous in-house quality systems

- Contract manufacturing services

- An FDA-approved, aseptic GMP facility

- Demonstrated lot-to-lot reproducibility with proven scale-up success

- A strong focus on communication and project management

- A track record of success for taking projects from proof of concept to clinical trials

If you’ve been searching for a trustworthy lab to work on your project and facilitate technology transfer for pharmaceuticals, choose Oakwood Labs. We have the facilities, expertise, and team needed to deliver.

Reach Out to Oakwood Labs Today

To ask our team questions about our processes, or to get started on a project, feel free to contact us. We’ll discuss your goals with you and help determine the best approach to realizing them.